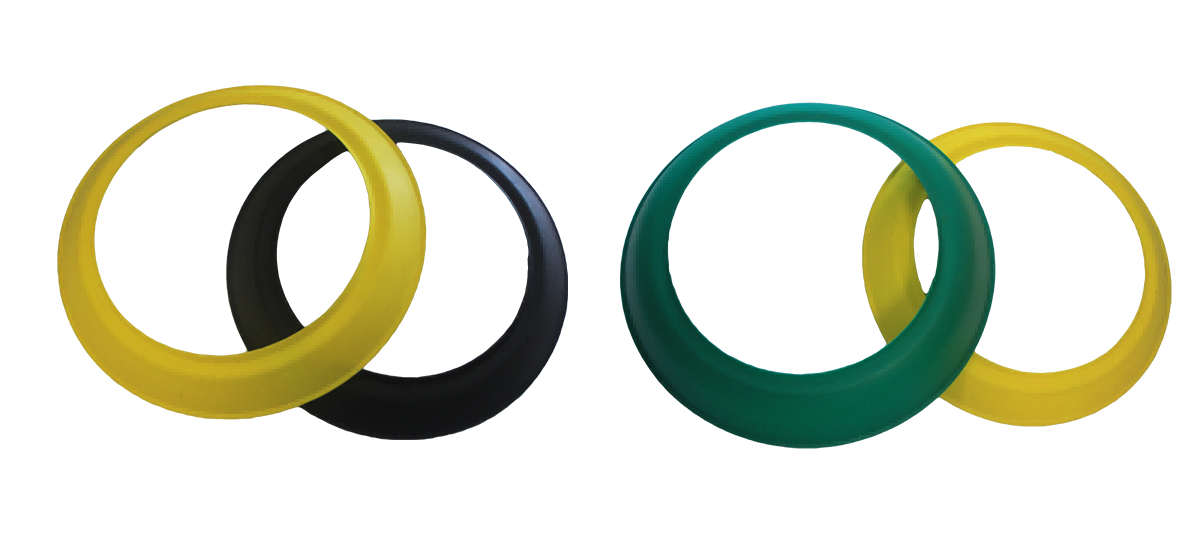

PP Tire Plate

- Changshu Eternal Prosperity

- Jiangsu

Parameters:

Shape: Customizable

Size: Customizable

Minimum order quantity:

No minimum order quantity

Company Profile:

The company is expanding production and relocating, and the factory area has been expanded to 3080 square meters.

Origin: China

Parameters:

Shape: Customizable

Size: Customizable

Minimum order quantity:

No minimum order quantity

Company Profile:

The company is expanding production and relocating, and the factory area has been expanded to 3080 square meters. Continuously enriching the product line, focusing on areas such as automotive interior parts and medical devices, with an annual production capacity increased to 3 million sets. The design team uses design software such as Unigraphics, Mastercam, Powerwill, Catia, etc. to provide professional services in product design, part deepening, mold design, mold making, and injection molding. The production equipment includes 3 CNC machining centers, 3 Beijing precision carving centers, 4 wire cutting centers, and mold making equipment such as lathes, milling machines, grinders, and electric discharge machines. We also provide 16 injection molding processing equipment for 50-800 tons. Serving enterprises such as Malosa Medical, Aneng Medical, Jaguar, Land Rover, Volkswagen, Michelin tires, and Zhengxin tires.

Material :PP

Product Introduction:

Disc-shaped impact resistant plastic tyre plate made of PPalso known as bead spacer and tire pad. Used for separateeach rubber tire while piling them up during production, thecurve of tire plate is designed to match perfectly with theshape of tire as well as to fix and maintain the shape of tires.With the tire plate, the tire can not only be placed neatly butalso be sorted systematic by size. We have a wide size choiceranges from 13~22 inches.

FAQ

Application and influence of triangular rubber shaping disc in tire production

Tire production is a complex and precise process, in which the triangular rubber shaping plate plays a crucial role in improving tire quality and production efficiency. As an important component of a tire, the tire bead is composed of a steel wire ring and a triangular rubber strip. The triangular rubber strip is attached to the steel wire ring, playing a key role in filling and fixing the steel wire ring. This bonding process cannot be separated from an efficient and reliable triangular rubber shaping disc.

In the traditional tire production process, there are many pain points in the triangular rubber bonding process. The manual labor intensity is high, the technical requirements for operators are high, and the safety is low. At the same time, the quality of the triangular adhesive bonding joints is unstable, the production efficiency is low, and it is difficult to adjust the specifications frequently. It also requires manual sorting to complete the circle. These problems not only increase production costs, but also make it difficult to ensure the consistency of product quality. The application of triangular adhesive shaping discs, especially the emergence of advanced triangular adhesive bonding production lines, has greatly improved this situation.

Taking the new generation PCR triangular adhesive bonding production line launched by Zhongyi Company as an example, it has made significant breakthroughs in one click start-up, rapid specification switching, and AI intelligent detection. The horizontal laminating machine of this production line has successfully developed multi inch laminating discs, each of which can be used to laminate 3-5 inch steel wire rings, filling the gap in the industry of "continuous production without the need to replace laminating discs". Both horizontal and vertical laminating machines have achieved true one click start, intelligently managing system laminating parameters. Operators only need to touch buttons on the touch screen to switch specifications, solving industry pain points such as cumbersome manual adjustment of specifications, long switching time, and unstable laminating quality in the past. This greatly improves work efficiency and effectively ensures product quality. At the same time, the intelligent sorting function of the system has been achieved through the AI intelligent recognition system, which, together with the automated logistics production line, can realize the automatic operation of the system and the inspection function of multiple machines by one person, further improving production efficiency and reducing labor costs.

In actual production, the performance of the triangular rubber shaping disc directly affects the bonding quality between the triangular rubber and the steel wire ring. For example, if the surface accuracy of the bonding plate is insufficient or the feed position is set inaccurately, it will cause the triangular rubber to not fit tightly with the steel wire ring, resulting in problems such as bubbles and misalignment, seriously affecting the quality of the tire bead, and thus affecting the overall performance and safety of the tire. The optimized design of the bonding disc system, such as the improved all steel triangle rubber tire bead hot bonding production line bonding disc system, has improved the structural strength and surface accuracy of the bonding disc. It uses servo motors for precise positioning to achieve rapid feed and can accurately set the feed rate in the formula, effectively avoiding the above problems and improving the forming quality of the triangle rubber tire bead.

In addition, some innovative triangular rubber forming disc structures, such as transforming the traditional nine wheel synchronous drive into a three-point drive triangular rubber ring forming disc structure, not only reduce equipment power consumption, but also reduce wear and maintenance costs by changing the dovetail groove structure of the forming guide wheel to a linear bearing, improve equipment stability and service life, and provide strong guarantees for the sustained and efficient production of tires.

The application of triangular rubber shaping discs in tire production has fundamentally changed the drawbacks of traditional production modes. Through technological innovation, it has achieved efficient, precise, and intelligent production processes, providing solid technical support for tire enterprises to enhance competitiveness and achieve sustainable development. It has had a profound and positive impact on the development of the entire tire industry.