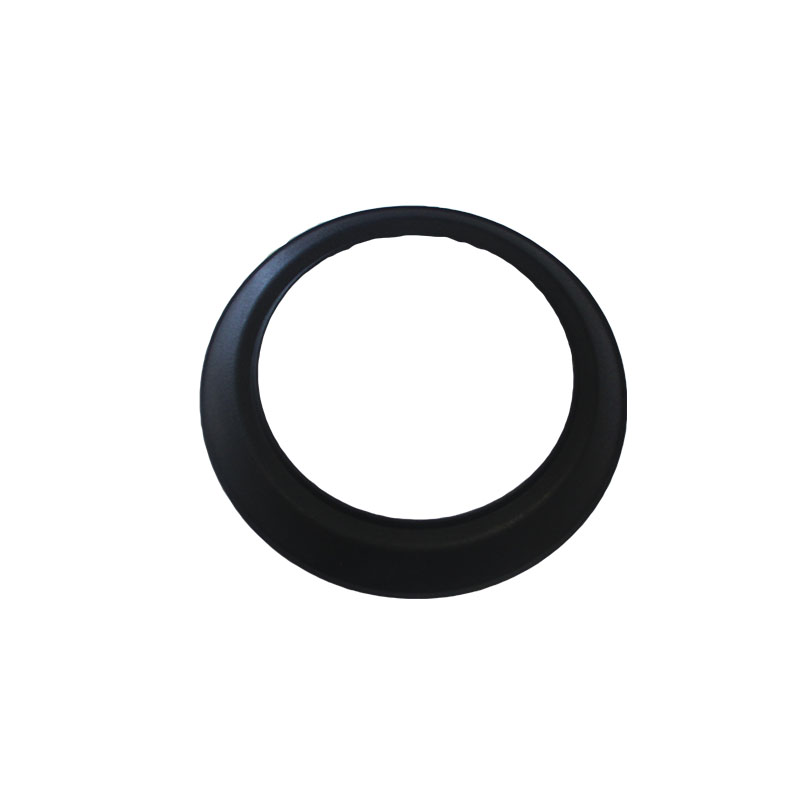

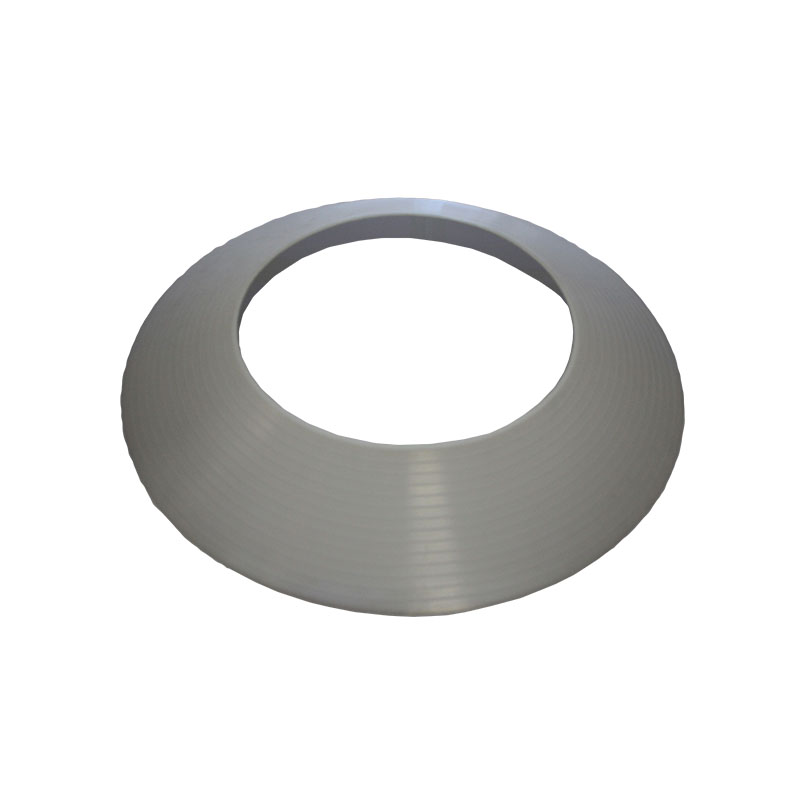

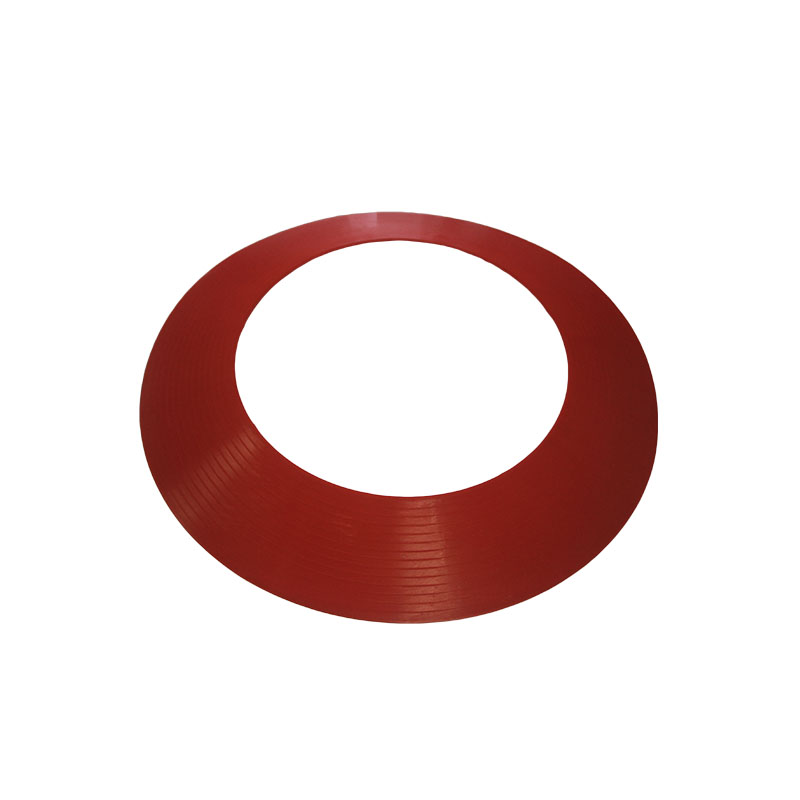

PP Tire Pad

- Changshu Eternal Prosperity

- Jiangsu

Product parameters:

Product Name: Plastic Surgery Plate

Specification: Customizable

Color: Customizable

Application scenario: Applied to rubber tires

Material: PP

Origin: China

Product parameters:

Product Name: Plastic Surgery Plate

Specification: Customizable

Color: Customizable

Application scenario: Applied to rubber tires

Material: PP

Product advantages:

The bead spacer has the advantages of no rubber bonding after tire molding, good tire molding quality, good heat dissipation, and no deformation during the molding process.

Product introduction:

In the production process of tires, Apex Holder is a type of rubber tire shaping partition. The Apex Holder is disc-shaped, and the curvature of the disc matches the rubber tire. There are several circles of protruding parts on the inner wall of the tire bead partition, a stepped part at the bottom of the shaping partition, a large through-hole in the middle of the partition, and a protruding part at the bottom and around the through-hole of the partition. The fixed partition is made of plastic.

Process application:

Triangle rubber tire partition is a type of rubber tire shaping partition, mainly used for placing steel wire triangle rubber isolation technology in the tire production process. Its characteristics are: the product is heat-resistant, anti sticking, and allows the steel wire triangle rubber to be shaped and stacked together. The Plastic tray is disc-shaped, and the curvature of the disc matches the rubber tire.

Company Introduction:

The company's main business scope includes the research and development, as well as production of metal fixtures, molds, medical gear molds, automotive parts, plastic products for minimally invasive surgical medical equipment, and plastic products for ophthalmic surgical medical equipment. Mainly serving customers in the automotive interior and medical device industries.

Annual production capacity:

3 million sets

Minimum order quantity:

Order as needed

Factory strength:

The production equipment includes 3 CNC machining centers, 3 Beijing precision carving machines, 4 wire cutting machines, and mold making equipment such as lathes, milling machines, grinders, and electric discharge machines. We also provide 16 injection molding processing equipment for 50-800 tons.

Customer service:

Serving enterprises such as Malosa Medical, Aneng Medical, Jaguar, Land Rover, Volkswagen, Michelin tires, Zhengxin tires, etc.

FAQ

Exploration into the Specification Adaptability of Triangular Plastic Forming Plates

In the field of radial tire production, the process of attaching the triangular rubber strip to the steel wire ring is crucial, as it plays a role in filling and fixing the steel wire ring. As a key equipment in this process, the size adaptability of the triangular rubber shaping disc has a profound impact on the efficiency and quality of tire production.

At present, most tire companies use radial tire triangle rubber fitting equipment, which exposes many problems when changing specifications. Most devices require the replacement of multiple adhesive discs, involving a large number of parts to be replaced, and the operation process is extremely complex and time-consuming, which seriously restricts the efficiency of tire bead forming. Under this traditional method, whenever faced with the need for different specifications of steel wire rings and triangular adhesives to fit together, workers need to spend a lot of energy and time on equipment adjustment, which not only delays production progress, but also frequently replaces components and may affect the final product quality due to installation errors and other factors.

However, the industry is also constantly exploring improvements to enhance the adaptability of the triangular rubber shaping disc specifications. Some innovative multi specification triangular adhesive bonding discs have emerged, such as a bonding disc that, through clever structural design, can quickly adjust the size of its fan-shaped disc expansion and contraction diameter according to the specifications of the steel wire ring. Specifically, the bonding plate includes a bonding plate, a connecting plate, an LM guide rail, a connecting rod component, a swing sleeve, a clamping component, an installation plate, a nylon sleeve, a swing driver, a top rod component, etc. Each bonding plate adopts a staggered cross structure, which is a unique design that allows the inclined surface of the bonding plate to be maintained within a certain tolerance range when adjusting the size level, and its applicable range spans up to 5 size levels. This greatly reduces the number of fixtures, saving costs and reducing labor intensity, allowing equipment to quickly switch between different specifications without the need for large-scale component replacement, significantly improving specification adaptability.

There are also some triangular rubber forming drum devices that can adjust the two ends of the flipper separately when changing specifications by setting a first adjustment device and a second adjustment device, which can promote the flipper to expand outward or contract inward, thereby allowing the triangular rubber forming drum device to adapt to different specifications of steel rings and triangular rubber. The entire adjustment process is easy to operate, greatly saving time, improving the universality and adaptability of the equipment, and laying a good foundation for the continuous action and automated production of the subsequent bonding between the triangular rubber and the steel ring.

In practical applications, Zhongyi Company's new generation PCR triangular adhesive bonding production line has made significant breakthroughs in terms of specification adaptability. The horizontal laminating machine has successfully developed multi inch laminating discs, each of which can be used to laminate 3-5 inch steel wire rings, filling the technical gap of "continuous production without replacing laminating discs" in the industry. Both PCR vertical and horizontal laminating machines have achieved multi inch continuous production. Operators only need to perform simple operations on the touch screen to switch specifications, solving the problems of manual adjustment, long switching time, and unstable bonding quality during specification alternation in the past. This greatly improves work efficiency and ensures product quality.