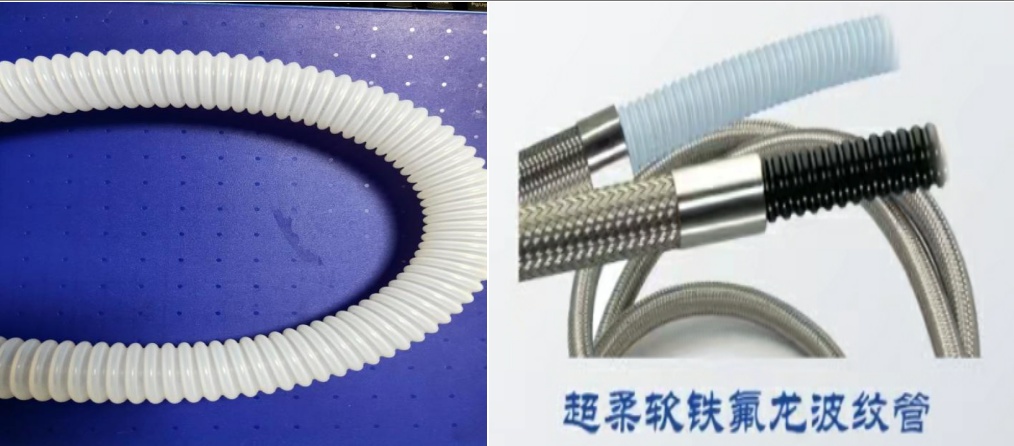

Ultra Soft Teflon Tube

- Changshu Eternal Prosperity

- Jiangsu

The company obtained ISO9000 certification in 2011;

Passed the 100000 level clean room inspection in 2022;

Obtained 16949 system certification in 2024.

Product performance :

1. Working temperature range: - 65 ℃ ~ + 260 ℃

2. Corrosion resistance, high temperature resistance, melting agent resistance

3. Non-sticky, non-humid, non-flammable

4. Low permeability, low coefficient of friction

5. Anti-weathering, anti-aging

6. Good electrical performance

Origin: China

The company is expanding production and relocating, and the factory area has been expanded to 3080 square meters. Continuously enriching the product line, focusing on areas such as automotive interior parts and medical devices, with an annual production capacity increased to 3 million sets. The design team uses design software such as Unigraphics, Mastercam, Powerwill, Catia, etc. to provide professional services in product design, part deepening, mold design, mold making, and injection molding. The production equipment includes 3 CNC machining centers, 3 Beijing precision carving centers, 4 wire cutting centers, and mold making equipment such as lathes, milling machines, grinders, and electric discharge machines. We also provide 16 injection molding processing equipment for 50-800 tons. Serving enterprises such as Malosa Medical, Aneng Medical, Jaguar, Land Rover, Volkswagen, Michelin tires, and Zhengxin tires.

Super soft Teflon bellows product description

1.Product structure: PTFE bellows + 304 or 316 single-layer or double-layer stainless steel wire braided

2. Product performance :

Working temperature range: - 65 ℃ ~ + 260 ℃

Corrosion resistance, high temperature resistance, melting agent resistance

Non-sticky, non-humid, non-flammable

Low permeability, low coefficient of friction

Anti-weathering, anti-aging

Good electrical performance

3. Product introduction :

Material: high temperature resistant, chemical resistant super soft PTFE bellows + single or double layer stainless steel wire braiding.

Small bending radius, super flexibility and kink resistance, the oil pipe can be stretched or extended frequently with the machine under high temperature environment, the service life is long, and the number of replacements is reduced.

Inner tube: 100% polytetrafluoroethylene resin, without any pigments and additives.

Braiding layer: 304 or 316 stainless steel wire can be selected.

Used for vulcanizing machine steam pipe ( applicable to the type of vulcanizing machine used )

Note: All braided tubes can increase anti-static (carbon) performance

4. Comparison between Teflon bellows and stainless steel bellows:

The Teflon corrugated pipe has good bending performance , super flexibility and kink resistance, and the oil pipe can be stretched or extended frequently with the machine in a high temperature environment, with a long service life and reduced replacement times.

Teflon bellows anti-fatigue, high pressure and pulse

Teflon tube buckle joint is firm and not easy to fall off.

The stainless steel bellows can withstand high temperature , but the low pressure is generally about 30 KG

Stainless steel bellows have poor bendability , and the solder joints are easy to crack when they are often bent, and the welding joints are also easy to fall off.

product | General bellows | Super soft and bendable Teflon bellows |

service life | 3~4 months | over 24 months |

use contrast | Advantages: cheap | Advantages: long service life, no need for frequent replacement , stable temperature, and reduced |

*Note: If the ultra-soft and flexible Teflon bellows have air leakage within 24 months of use, our company will replace the defective products for free. If your company needs a trial product, our company currently has a specification of 1*1600mm (1*1.6m), and the connector specification is 1"PH in the United States. If you need other specifications, you need to order it separately.

5. Product installation location

FAQ

Key details of installation of PTFE corrugated pipe

The installation quality of PTFE corrugated pipes directly affects their performance and service life. Even if they have the characteristics of easy installation, attention should still be paid to the following details to ensure the stability and safety of system operation.

1、 Accurate control of connection methods

Different connection methods need to match corresponding operating specifications. When using threaded connections, it is important to ensure that the threads are clean and undamaged. Special sealing agents can be applied appropriately (avoiding the use of materials that corrode PTFE), and the tightening force should be moderate. Excessive force may cause deformation of the corrugated pipe body or interface; When selecting a card sleeve connection, it is necessary to check whether the card sleeve model matches the pipe diameter, whether the card sleeve blade is intact, and ensure that the card sleeve is tightly attached to the pipe body during installation to prevent leakage caused by looseness. For corrugated pipes with flat head design, it is necessary to confirm that the flat head surface is smooth and free of burrs before installation, and that the contact surface with the connecting components is flat. If necessary, suitable sealing gaskets can be added to enhance the sealing performance.

2、 Advance consideration of environmental adaptability

The installation environment has a significant impact on the performance of PTFE corrugated pipes. In high-temperature environments (such as areas near boilers and heating equipment), sufficient expansion and contraction space should be reserved to avoid excessive stretching or compression of the corrugated pipe due to temperature changes. The stress caused by thermal expansion and contraction can be reduced by installing guide brackets; In low-temperature environments, attention should be paid to the flexibility changes of corrugated pipes to avoid forced bending at low temperatures and prevent cracks in the pipe body. If there is a vibration source near the installation location (such as near the pump body or fan), elastic support or shock-absorbing joints should be used to reduce the impact of vibration on the corrugated pipe interface and extend its service life.

3、 Reasonable planning of size and layout

Before installation, it is necessary to accurately measure parameters such as pipeline length and bending radius to ensure that the size of the corrugated pipe matches the actual requirements. The bending radius of the corrugated pipe shall not be less than its minimum allowable value (different specifications of products have different parameters, please refer to the product manual). Excessive bending will cause uneven stress on the pipe wall, affecting pressure resistance and flexibility; In pipeline layout, it is necessary to avoid the corrugated pipe bearing additional weight. It can be fixed by setting brackets, and the spacing between brackets should be adjusted reasonably according to the diameter of the pipe to prevent deformation of the corrugated pipe due to its own weight sagging. At the same time, it is necessary to ensure that the axis of the corrugated pipe is consistent with the axis of the connecting equipment to avoid eccentric installation, otherwise it will cause local stress concentration and shorten the service life.

4、 Detail handling of cleaning and protection

Before installation, it is necessary to clean the inside of the corrugated pipe to remove dust, impurities, etc. inside the pipe, in order to prevent blockage or contamination during fluid transportation (especially in the food and medical industries). For pipelines transporting corrosive media, installation tools should avoid using metal materials that can cause rust to prevent rust stains on the surface of the tool from contaminating the inner wall of the corrugated pipe. After installation, the interface area needs to be protected. If it is not put into use for a long time, sealing should be installed at both ends to prevent dust and water vapor from entering the pipe.

5、 Testing and verification after installation

After installation, a pressure test (set the test pressure according to the actual working pressure) is required to observe whether there is any leakage at the interface, and at the same time, check whether there is any abnormal deformation of the corrugated pipe body. For pipelines transporting flammable and explosive media, air tightness tests are also required to ensure that the system's sealing meets safety standards. During the testing process, if any problems are found, they should be dismantled and reinstalled in a timely manner to avoid forcefully adjusting and damaging the corrugated pipe.