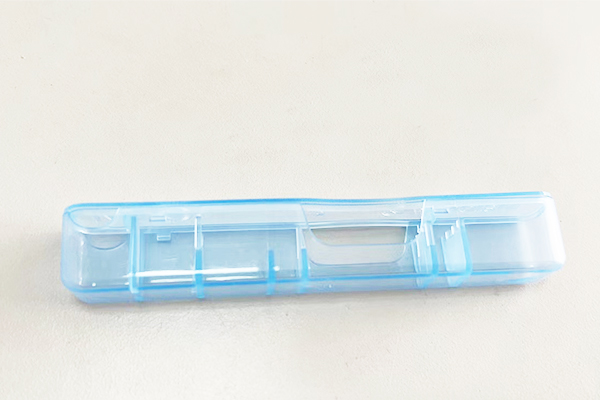

Medical Plastic Box

- Changshu Eternal Prosperity

- Jiangsu

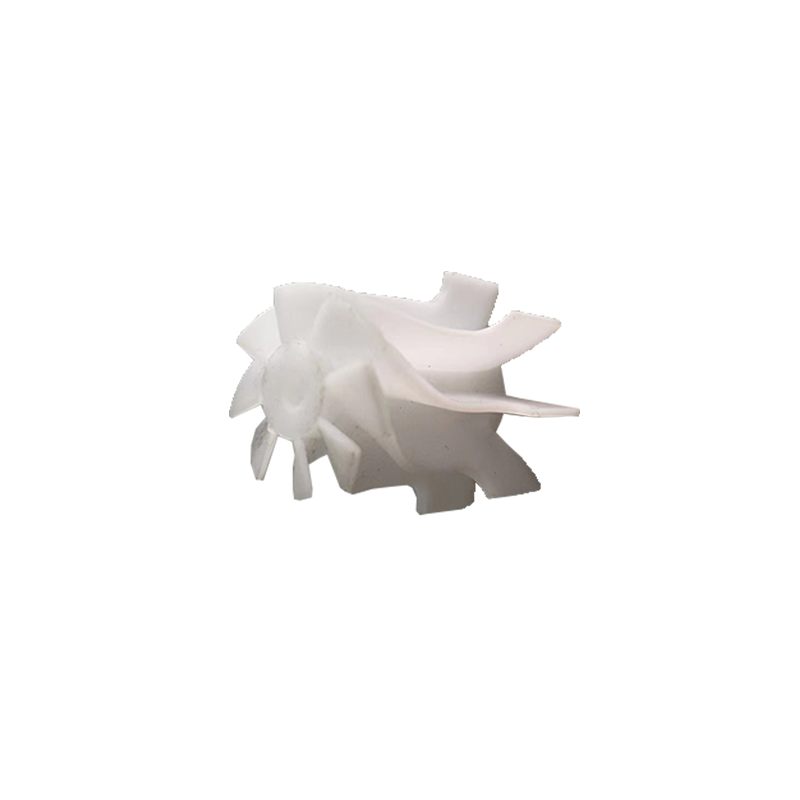

Our company sells medical plastic accessories;

The company obtained ISO9000 certification in 2011;

Passed the 100000 level clean room inspection in 2022;

Obtained 16949 system certification in 2024.

Product parameters:

Colors can be customized; The shape can be customized; Materials can be customized; Support customized drawings.

Company Introduction:

The company's main business scope includes the research and development, as well as production of metal fixtures, molds, medical gear molds, automotive parts, plastic products for minimally invasive surgical medical equipment, and plastic products for ophthalmic surgical medical equipment. Mainly serving customers in the automotive interior and medical device industries.

Enterprise Qualification:

The company obtained ISO9000 certification in 2011; Passed the 100000 level clean room inspection in 2022; Obtained 16949 system certification in 2024; We also have over ten patent certificates.

Advantages of production equipment:

1. The production equipment includes 3 CNC machining centers, 3 Beijing precision carving centers, 4 wire cutting centers, and mold making equipment such as lathes, milling machines, grinders, and electric discharge machines. We also provide 16 injection molding processing equipment for 50-800 tons.

Advantages of detection equipment:

The detection environment temperature is 23 ° C ± 2 ° C

Quality of raw materials for product processing:

The company has always insisted on using high-quality products from imported or wholly-owned factories for the raw materials of key product components. Starting from reducing profits, energy conservation, expanding production, and increasing sales, we will never lower the requirements for raw materials and production processes, fundamentally ensuring the quality of our products.

FAQ

The 'high threshold' of medical plastic products: how to cope with strict industry requirements?

Medical plastic products are an important component of the medical device and packaging industry, but their production and use face multiple challenges:

1. Strict biocompatibility requirements

Medical plastics must pass biocompatibility tests such as ISO 10993 to ensure non toxicity and non allergenicity. For example, plastics in infusion sets and implanted devices need to come into long-term contact with the human body, and any precipitates may pose risks.

2. Compatibility issues with sterilization

Sterilization methods such as high-temperature steam, ethylene oxide (EO), and irradiation may cause plastic aging or performance degradation. For example, PVC is prone to deformation at high temperatures, while some materials become brittle after irradiation.

3. Cost and supply chain pressure

Medical grade plastic raw materials (such as medical grade PP and PEKK) are expensive and rely on imports. In recent years, global supply chain fluctuations have further intensified cost pressures.

4. Solution:

Material modification technology: Enhancing sterilization resistance by adding stabilizers.

Domestic substitution: Promote the research and development of domestic medical grade resins and reduce dependence on imports.

Digital quality control: using AI to detect product defects and reduce defect rates.