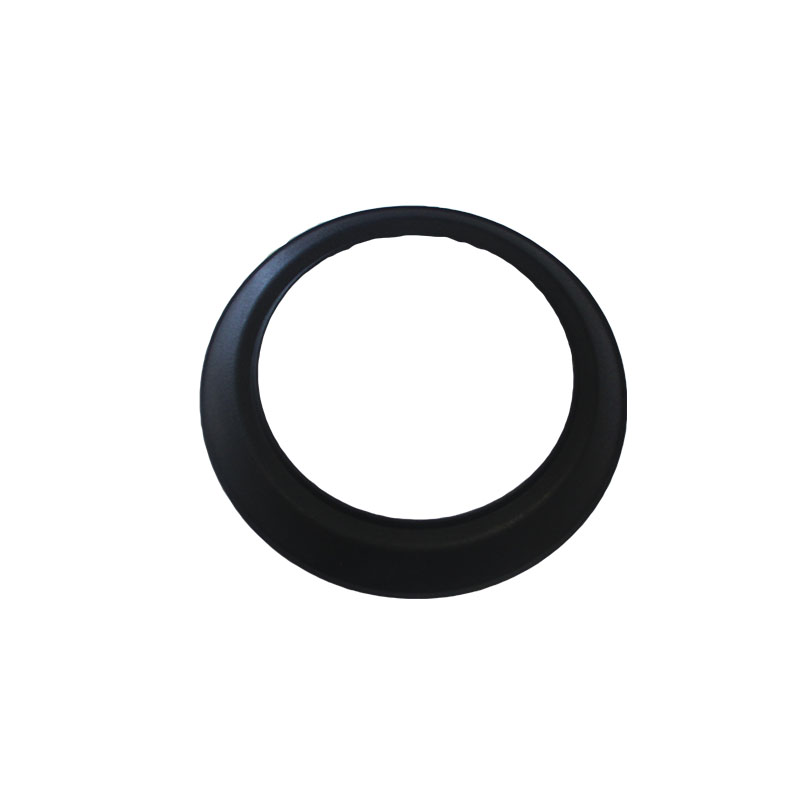

PP Rubber tray

- Changshu Eternal Prosperity

- Jiangsu

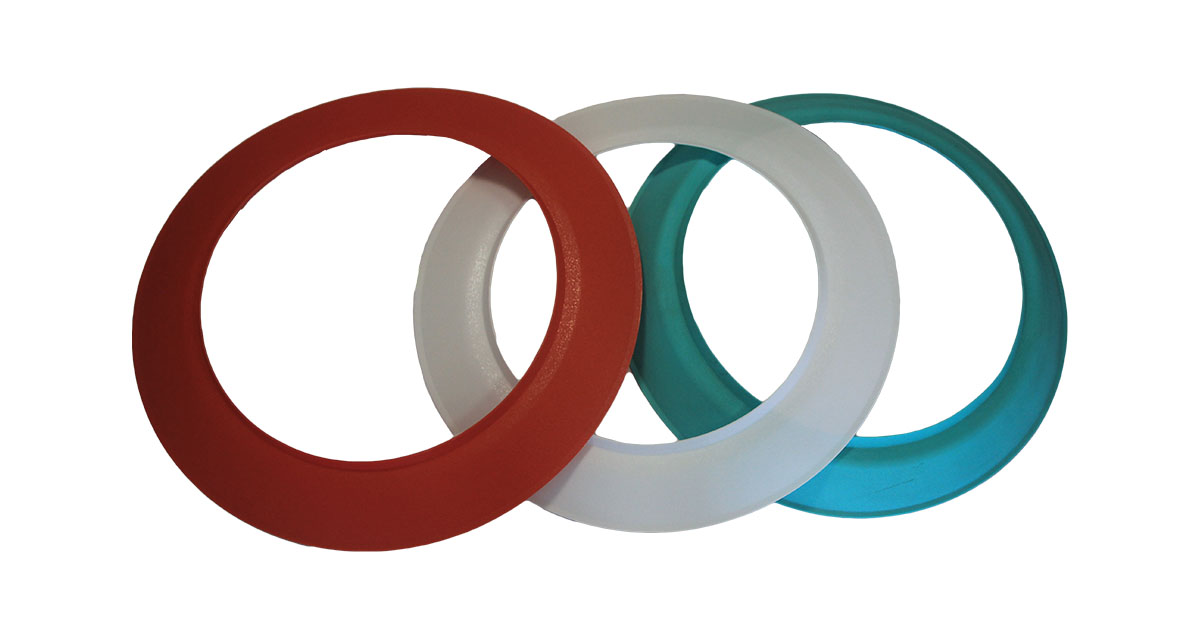

Product Description:

Triangle rubber shaping plate (bead separator) is a plastic shaping plate used for tire molding. It adopts a disc-shaped design, and its curvature perfectly matches the rubber tire, ensuring precise positioning and stable molding.

Structural characteristics

·Inner cavity sidewall: equipped with multiple circles of protrusions to enhance positioning effect and prevent rubber material deviation.

·Bottom staircase: Optimize the support structure to enhance overall stability.

·Central through-hole: equipped with a larger through-hole for easy heat dissipation and process operation.

·Bottom protrusion: located around the through-hole to further reinforce the structure and prevent deformation.

Product advantages

·Anti bonding: Ensure that the rubber material does not stick after tire molding, improving demolding efficiency.

·High precision molding: Optimize tire molding quality and reduce defect rates.

·Good heat dissipation: The through-hole design accelerates heat dissipation and avoids overheating and deformation.

·Durable and non deformable: The plastic material is sturdy and stable, maintaining precise shape even after long-term use.

Application value

·Suitable for the production of various types of rubber tires, it effectively improves molding efficiency and product consistency, and is a key auxiliary component in the tire manufacturing process.

Product Description:

A bead separator is a plastic shaped partition used for tire molding, featuring a disc-shaped design that perfectly matches the curvature of rubber tires, ensuring precise positioning and stable molding.

Structural characteristics

Inner cavity sidewall: equipped with multiple circles of protrusions to enhance positioning effect and prevent rubber material deviation.

Bottom staircase: Optimize the support structure to enhance overall stability.

Central through-hole: equipped with a larger through-hole for easy heat dissipation and process operation.

Bottom protrusion: located around the through-hole to further reinforce the structure and prevent deformation.

Product advantages

Anti bonding: Ensure that the rubber material does not stick after tire molding, improving demolding efficiency.

High precision molding: Optimize tire molding quality and reduce defect rates.

Good heat dissipation: The through-hole design accelerates heat dissipation and avoids overheating and deformation.

Durable and non deformable: The plastic material is sturdy and stable, maintaining precise shape even after long-term use.

Application value

Suitable for the production of various types of rubber tires, it effectively improves molding efficiency and product consistency, and is a key auxiliary component in the tire manufacturing process.

Characteristics of triangular rubber shaping plate products:

1. High temperature resistance

2. Anti sticking

3. It is a type of fixed partition used for rubber tires

Company Introduction:

1. Expansion relocation and factory upgrading

The company is expanding production and relocating, and the factory area has been expanded to 3080 square meters.

2. Product line and production capacity

Continuously enriching the product line, focusing on areas such as automotive interior parts and medical devices.

The annual production capacity has increased to 3 million sets.

3. Design ability and software application

The design team uses design software such as Unigraphics, Mastercam, Powerwill, Catia, etc.

Provide professional services such as product design, parts deepening, mold design, mold making, injection molding, etc.

Product quality control:

To ensure the quality standards of the product and provide customers with reliable and safe products. The raw materials for key product components of the company have always insisted on using imported or wholly-owned factories' high-quality products. Starting from reducing profits, energy conservation, expanding production, and increasing sales, we will never lower the requirements for raw materials and production processes, fundamentally ensuring the quality of the products.

Product manufacturing video of Changshu Yongquansheng Hardware Products Co., Ltd.

Qualification certification:

The company obtained ISO9000 certification in 2011; Passed the 100000 level clean room inspection in 2022; Obtained 16949 system certification in 2024.

FAQ

Where is the tire bead separator used?

Core purpose:

The bead spacer (also known as the triangular rubber shaping plate) is a key auxiliary mold in the tire manufacturing process, mainly used for the molding and shaping of the tire bead area, ensuring accurate positioning of the triangular rubber (bead filling rubber) and maintaining structural stability.

Specific application scenarios:

1. Tire Forming Stage

During the assembly of semi-finished tires, the bead separator serves as a supporting mold to fix the position of the triangular rubber and prevent it from shifting or deforming.

Ensure that the triangular rubber is tightly adhered to the tire bead wire, tire body curtain and other components to avoid defects such as bubbles and wrinkles.

2. Vulcanization molding process

In the high-temperature and high-pressure environment of the vulcanization tank, the stepped structure and protrusions of the partition can evenly distribute pressure and prevent tire bead deformation.

The central through-hole design promotes heat circulation, improves vulcanization efficiency, and reduces rubber deformation caused by thermal stress.

3. Applicable tire types

Manufacturing of radial tires such as passenger car tires, truck tires, and construction machinery tires.

Especially suitable for high-performance tires with high requirements for bead strength, such as anti blowout tires and off-road tires.

4. Why is it indispensable?

Accuracy guarantee: The disc curvature and protrusion design match the tire contour to ensure consistent molding.

Efficiency improvement: Reduce manual adjustments and accelerate production pace.

Quality optimization: Avoid problems such as adhesive adhesion and bead deformation, and extend the service life of tires.