PP Plastic Tray

- Changshu Eternal Prosperity

- Jiangsu

Origin: China

Product parameters:

Specification: Customizable

Color: Customizable

Material: PP

Shape: Customizable

Product features:

1. Good qu

Product process:

Triangle rubber shaping plate (bead partition) is a type of rubber tire shaping partition, mainly used for placing steel wire triangle rubber isolation process in the tire production process.

Company advantages:

1. Continuously enriching the product line, focusing on automotive interior parts, medical devices and other fields, with an annual production capacity increased to 3 million sets;

2. The production equipment includes 3 CNC machining centers, 3 Beijing precision carving centers, 4 wire cutting centers, and mold making equipment such as lathes, milling machines, grinders, and electric discharge machines. We also provide 16 injection molding processing equipment for 50-800 tons.

Enterprise Qualification:

1. The company obtained ISO9000 certification in 2011; Passed the 100000 level clean room inspection in 2022; Obtained 16949 system certification in 2024

2. Having over 10 patented technologies

Company sales and customers:

The company's main business scope includes the production of metal fixtures, molds, medical gear molds, automotive parts, plastic products for minimally invasive surgical medical equipment, and plastic products for ophthalmic surgical medical equipment research and development and production. Mainly serving customers in the automotive interior and medical device industries.

Product manufacturing video of Changshu Yongquansheng Hardware Products Co., Ltd.

FAQ:

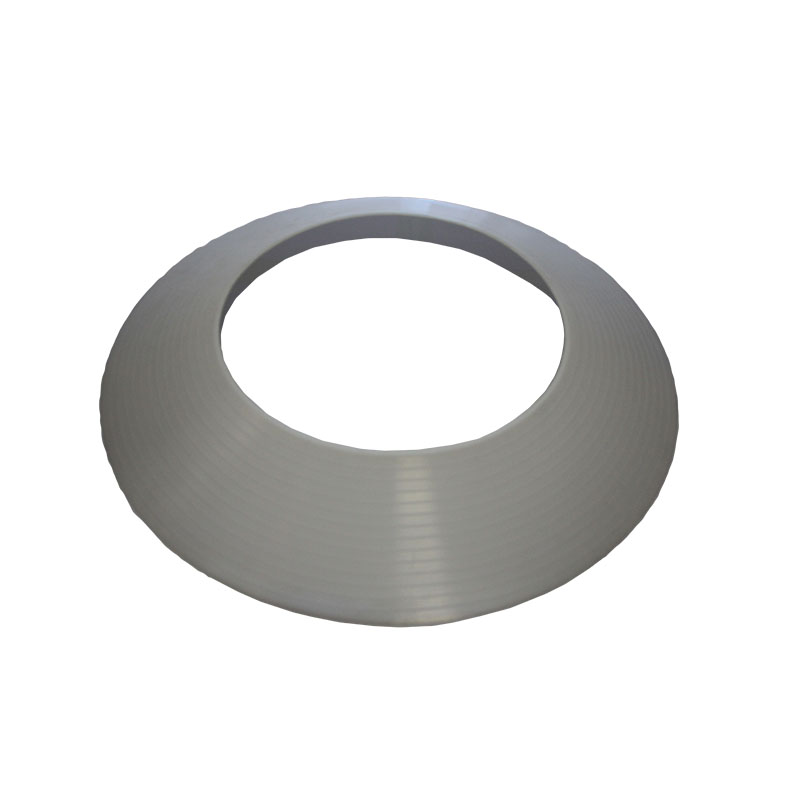

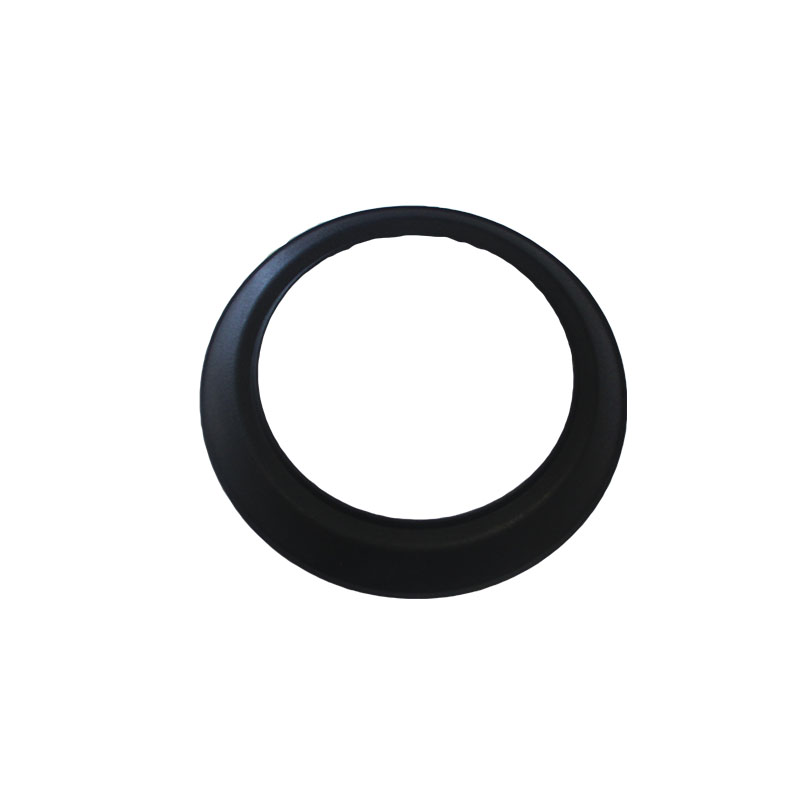

Structural Design and Core Function Analysis of Tire Bead Partition

In the manufacturing of radial tires, although the bead spacer (triangular rubber shaping plate) is inconspicuous, it is a key mold to ensure the accuracy of bead forming. Its unique structural design directly determines the durability and safety of the tire.

1. Revealing Structural Design

Circular curvature: perfectly matches the tire bead curve, ensuring no error in the fitting of the triangular rubber.

Multi circle protrusion: The protruding structure on the inner wall fixes the position of the rubber material to prevent flow deformation during vulcanization.

Bottom of staircase+central through-hole: The staircase enhances support, and the through-hole accelerates heat dissipation to avoid thermal stress deformation.

2. Core functions

Anti adhesion: The surface of the plastic material is smooth to prevent the adhesive from sticking to the mold.

Accurate shaping: Lock the triangular rubber through the protruding part to ensure even wrapping of the tire bead wire.

Heat dissipation optimization: Through hole design enables rapid dissipation of sulfurization heat and shortens process time.