Automatic Tire Pallet

- Changshu Yongchengsheng Hardware

- Jiangsu

In 2002, Changshu Yongchengsheng Hardware Products Co., Ltd. emerged in the wave of manufacturing industry and settled in the economically active and conveniently located Changshu area. For over 20 years, the company has always adhered to the core development philosophy of "excellence in quality, sincerity in trust, and innovation". It has gradually grown from a small processing enterprise to a benchmark enterprise in the field of injection molding plastics, forming a complete industrial chain integrating product creative design, precision mold development, large-scale production, and system integration services, providing global customers with comprehensive hardware and plastic solutions.

In 2002, Changshu Yongchengsheng Hardware Products Co., Ltd. emerged in the wave of manufacturing industry and settled in the economically active and conveniently located Changshu area. For over 20 years, the company has always adhered to the core development philosophy of "excellence in quality, sincerity in trust, and innovation". It has gradually grown from a small processing enterprise to a benchmark enterprise in the field of injection molding plastics, forming a complete industrial chain integrating product creative design, precision mold development, large-scale production, and system integration services, providing global customers with comprehensive hardware and plastic solutions.

Technology drives innovation, R&D empowers development

Technology research and development is the core competitiveness of Yongshengsheng Hardware. The company is well aware that in the wave of transformation and upgrading in the manufacturing industry, only continuous innovation can maintain a leading position. Therefore, it has established an independent R&D center and equipped a professional R&D team led by senior engineers, including technical experts with more than ten years of industry experience. The R&D team closely tracks the forefront of industry technology, conducts in-depth research on market demand, and invests over 8% of its annual revenue into the development of new technologies and products.

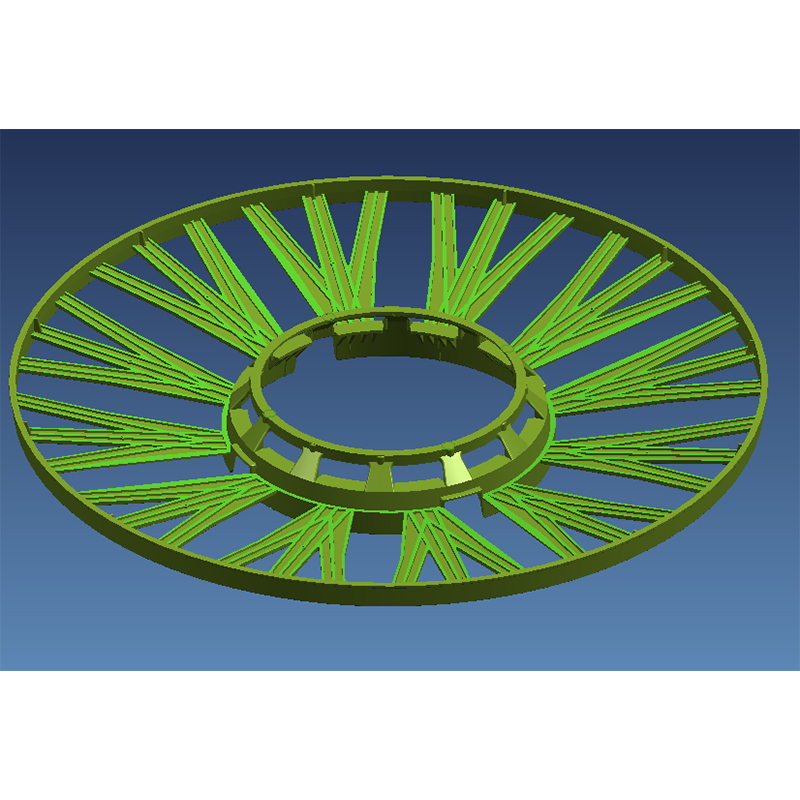

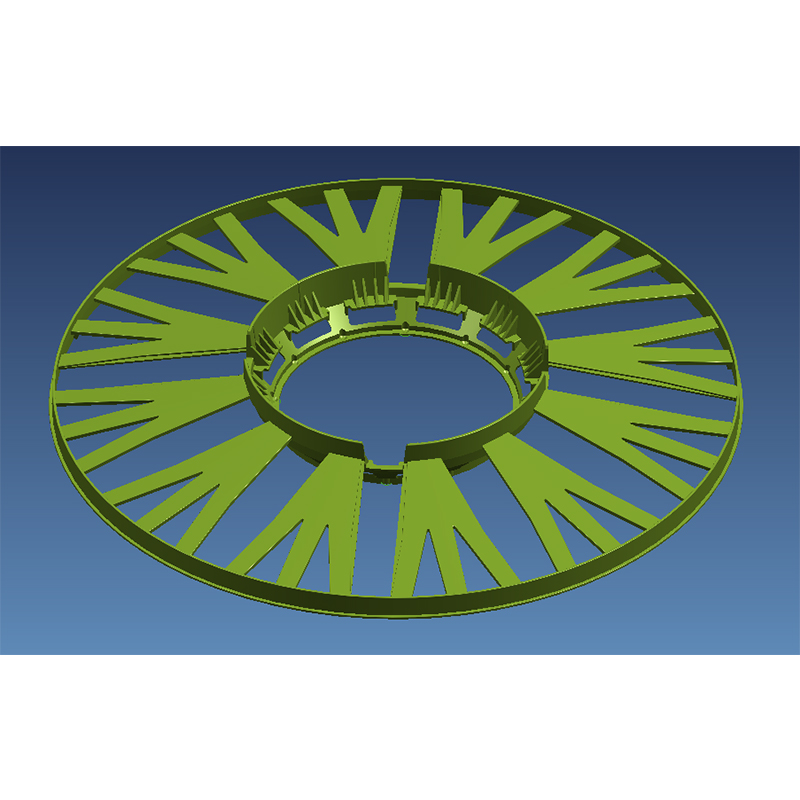

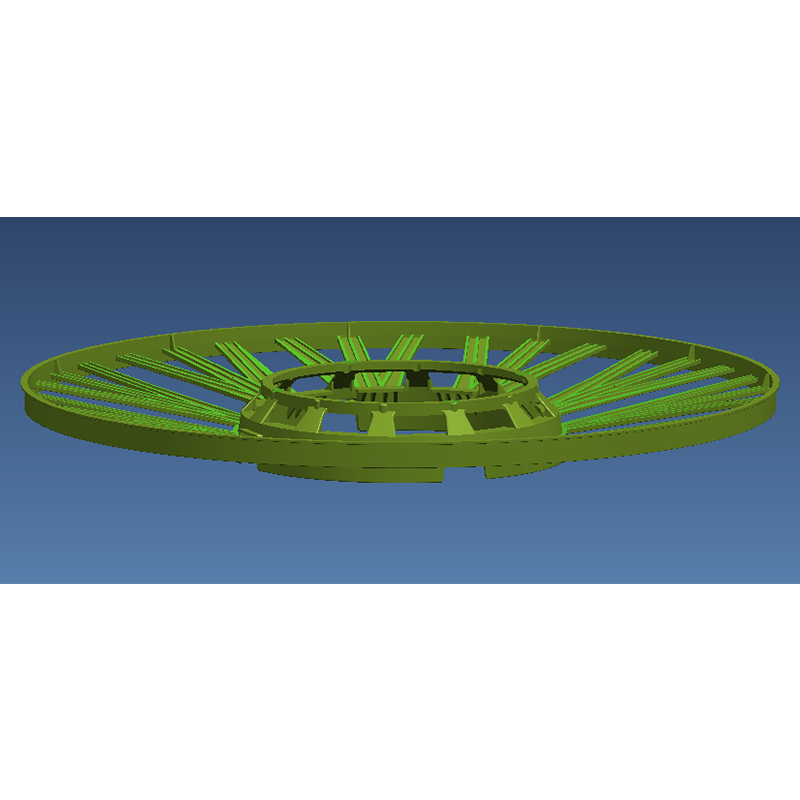

In the product design process, the company adopts advanced 3D modeling and simulation technology to achieve digitalization and visualization of product design, effectively shortening the product development cycle; In terms of mold manufacturing, by introducing high-precision processing equipment and advanced technology, multiple technical difficulties such as complex cavity mold processing and small part forming have been overcome. The mold accuracy can reach 0.005mm, ensuring the consistency and stability of injection molded products. With strong research and development capabilities, the company has obtained multiple utility model patents, and multiple products have been awarded the title of industry quality products for their innovation and practicality.

Strict quality control, creating a benchmark for quality

The concept of 'quality is the lifeline of an enterprise' is deeply rooted in the entire production and operation process of Yongshengsheng Hardware. The company has established a full process quality control system from raw material procurement to finished product delivery, achieving seamless coverage of quality supervision. In the process of raw material procurement, the company has established long-term strategic partnerships with multiple well-known domestic and foreign raw material suppliers, conducting strict physical and chemical performance testing on each batch of raw materials. Only raw materials that meet the standards can enter the production process; In the production process, dedicated quality inspection personnel are equipped, and a triple inspection mode of "first piece inspection+patrol inspection+last piece inspection" is adopted. With the help of high-precision inspection equipment such as three-dimensional coordinate instruments and tensile testing machines, multiple indicators such as product size, strength, and appearance are comprehensively inspected; Before the finished product is released from the warehouse, it needs to undergo final sampling inspection to ensure that every product delivered to the customer meets the quality requirements.

In addition, the company has also introduced the ISO9001 quality management system, which standardizes the production and operation processes through standardized management procedures, further enhancing the stability of product quality. It is precisely this strict quality control attitude that has earned the company's products high recognition from domestic and foreign customers, and the products are exported to many countries and regions such as Europe, Southeast Asia, and North America.

Accurate market positioning, expanding diversified territory

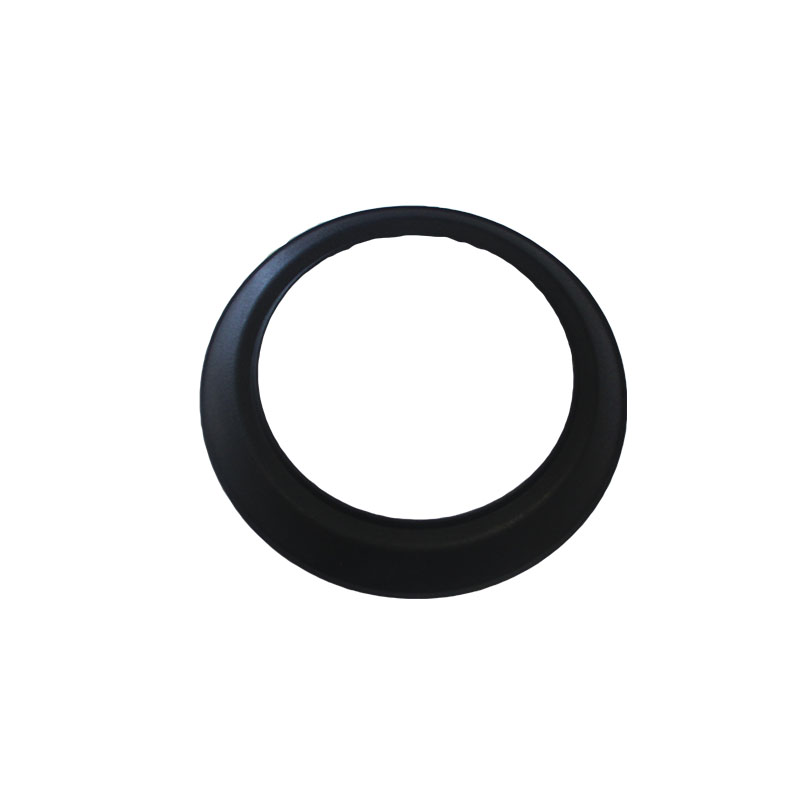

Based on market demand, the company has precisely laid out two core business segments, forming a mutually supportive and collaborative development business pattern. In the production and manufacturing sector, focusing on the supporting needs of the tire industry, we have created a series of core products such as triangular rubber shaping discs and tire separators. With the high adaptability and durability of our products, we have established long-term stable cooperative relationships with multiple large tire enterprises and become their core supporting suppliers; In the wholesale import and export sector, we focus on cultivating high value-added fields such as medical, automotive, and electronic appliances, and provide customized plastic product solutions.

Among them, the medical plastic product series strictly follows GMP production standards and is produced and processed in clean room workshops to ensure that the products meet medical grade cleanliness requirements. They are widely used in medical device assembly, drug packaging, and other scenarios; Automotive plastic products have developed and produced various high-strength and high-temperature resistant structural components and interior parts to meet the production needs of new energy vehicles and traditional fuel vehicles, in response to the trend of lightweighting and intelligence in automobiles; Electronic and electrical plastic products have become the preferred partners for many electronic equipment manufacturers due to their excellent insulation performance and precise dimensions.

Adhering to the concept of win-win, looking forward to a new chapter in the future

Customer needs as the center and mutual benefit as the goal "is the business philosophy that Yongshengsheng Hardware has always adhered to. The company has established a comprehensive customer service system, equipped with a professional service team to follow up on the entire process from early demand communication and customized solutions, to mid-term production follow-up and sample confirmation, to later logistics distribution and after-sales support, ensuring timely response and effective satisfaction of customer needs. For long-term cooperative customers, the company will also provide regular follow-up services to understand product usage, collect improvement suggestions, and continuously optimize products and services.

Looking ahead to the future, Changshu Yongchengsheng Hardware Products Co., Ltd. will continue to be driven by technological innovation, guaranteed by quality control, continuously expand its business areas, and enhance its core competitiveness. We plan to further increase investment in intelligent equipment and promote the automation upgrade of production processes; At the same time, we will strengthen cooperation with universities and research institutions, overcome more technical challenges in various industries, and develop more high value-added products. The company firmly believes that through cooperation with customers and collaborative development with the industry, it will write a more brilliant chapter in the field of hardware and plastic manufacturing, and achieve a higher level of mutual benefit and win-win results!