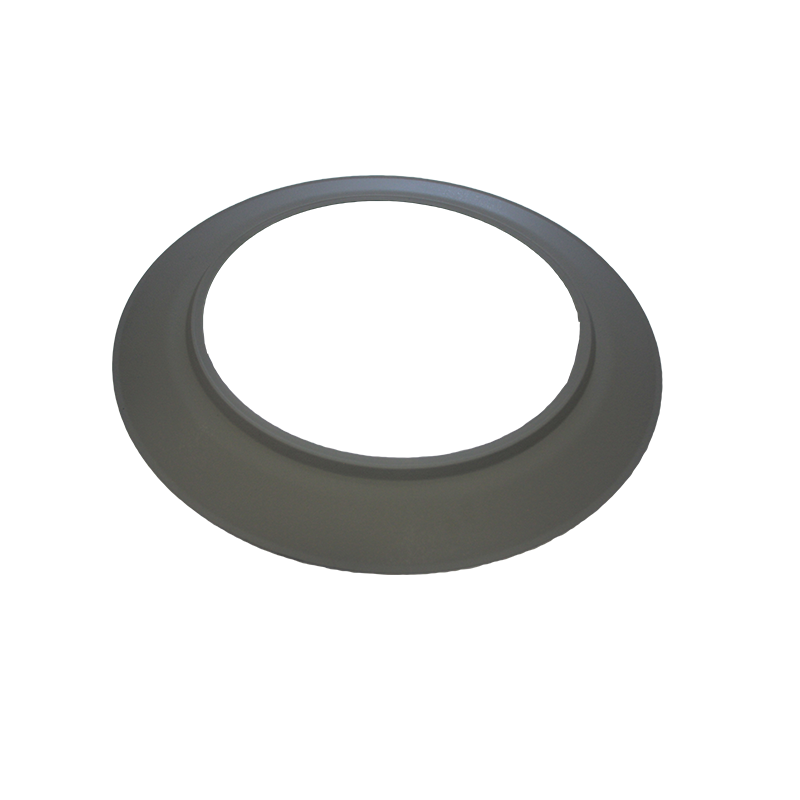

PP Bead Spacer

- Changshu Eternal Prosperity

- Jiangsu

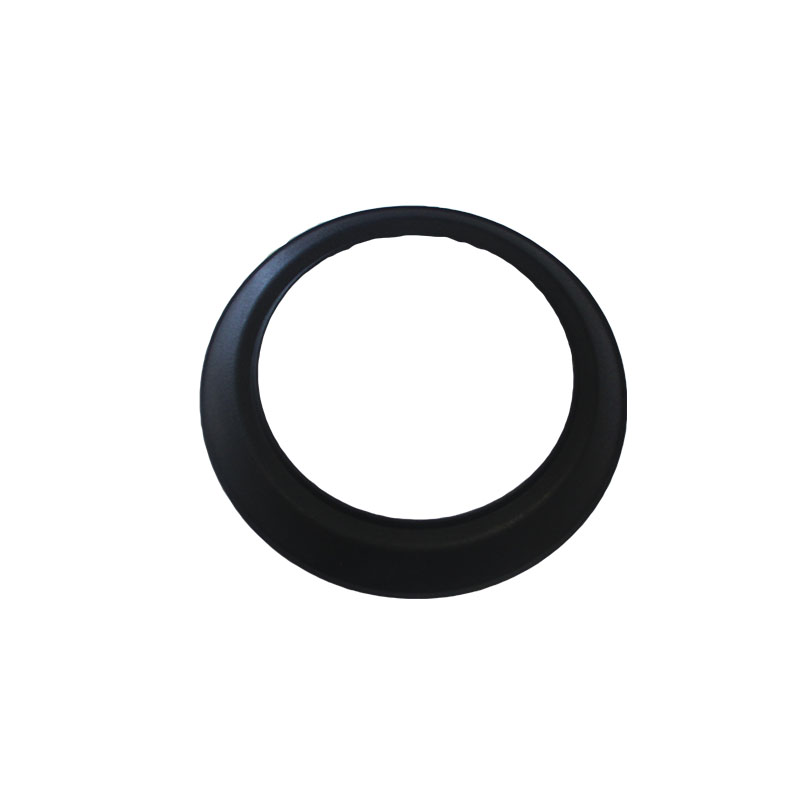

Product Introduction:

A disc-shaped impact resistant plastic tire plate made of PP, also known as bead washer and tire liner. In the production process, it is used to separate and stack each rubber tire, and the curve of the tire plate is designed to perfectly match the shape of the tire, and to fix and maintain the shape of the tire. With tire plates, tires can not only be neatly placed, but also systematically classified by size. We have a wide size selection of 13-22 inches

Product Introduction:

A disc-shaped impact resistant plastic tire plate made of PP, also known as bead washer and tire liner. In the production process, it is used to separate and stack each rubber tire, and the curve of the tire plate is designed to perfectly match the shape of the tire, and to fix and maintain the shape of the tire. With tire plates, tires can not only be neatly placed, but also systematically classified by size. We have a wide size selection of 13-22 inches

Product parameters:

Product Name: Plastic Surgery Plate

Color: Green

Specification: 22.5 "zero degree ∅ B40 * ∅ 570 * 2

Product advantages:

The triangular rubber shaping disc (bead separator) has the advantages of no rubber bonding after tire molding, good tire molding quality, good heat dissipation, and no deformation during the molding process

Product features:

The product is heat-resistant, anti sticking, and allows the steel wire triangular rubber to be stacked and shaped. The triangular rubber shaping plate (tire bead partition) is disc-shaped, and the curvature of the disc-shaped plate matches the rubber tire.

Enterprise Information Introduction:

The company focuses on the fields of automotive interior parts, medical devices, etc., with an annual production capacity of 3 million sets. The design team uses design software such as Unigraphics, Mastercam, Powerwill, Catia, etc. to provide professional services in product design, part deepening, mold design, mold making, and injection molding. The production equipment includes 3 CNC machining centers, 3 Beijing precision carving centers, 4 wire cutting centers, and mold making equipment such as lathes, milling machines, grinders, and electric discharge machines. We also provide 16 injection molding processing equipment for 50-800 tons. Provide customers with good products.

cooperative partner:

Serving enterprises such as Malosa Medical, Aneng Medical, Jaguar, Land Rover, Volkswagen, Michelin tires, and Zhengxin tires.

FAQ

How can tire bead separators improve tire production efficiency?

Efficiency pain points:

In traditional tire molding, manually adjusting the position of the triangular rubber is time-consuming and prone to errors, resulting in a high deformation rate of the tire bead after vulcanization.

The principle of increasing efficiency of tire bead separators:

1. Standardized positioning

The protruding part and stepped structure of the partition achieve automatic alignment of the triangular adhesive, reducing manual intervention.

2. Rapid heat dissipation

The through-hole design shortens the vulcanization cycle by about 15% and significantly increases production capacity.

3. Reduce defect rate

Precise shaping reduces issues such as bead bubbles and eccentricity, resulting in a rework rate reduction of over 30%.