Auto Tire pad

- Changshu Yongchengsheng Hardware

- Jiangsu

Changshu Yongchengsheng Hardware Products Co., Ltd. was established in 2002. It is a company mainly engaged in injection molded plastic products, integrating design, molds, and systems. It currently has more than 50 employees. The main business scope of the company is engaged in the production and sales of mechanical hardware products, triangular rubber shaping discs, tire separators, bead separators, tire trays, and tire peripheral product accessories. It also engages in the wholesale and import/export of plastic products, medical plastic products, medical plastic parts, medical plastic products, medical plastic accessories, medical plastic pipes, medical plastic boxes, medical plastic products, automotive plastic products, and new electronic and electrical plastic components.

Changshu Yongchengsheng Hardware Products Co., Ltd. has been rooted in the Jiangnan water town of Changshu since 2002. After more than 20 years of deep cultivation and innovation iteration, it has developed into a comprehensive manufacturing enterprise with injection molded plastic products as the core pillar, integrating product design and research and development, precision mold manufacturing, and system integration solutions. The company has established a good reputation in the industry with stable product quality, forward-looking technology layout, and thoughtful service system. Currently, it has a professional team of more than 50 people, with technology research and development and core production backbone accounting for over 40%, injecting strong momentum into the sustainable development of the enterprise.

Diversified business layout, covering multiple fields of demand

The company is based in the field of hardware and plastic manufacturing, and has built a business pattern driven by "production and manufacturing+wholesale import and export". The product matrix is rich and accurately covers multiple segmented markets, forming a strong market competitiveness.

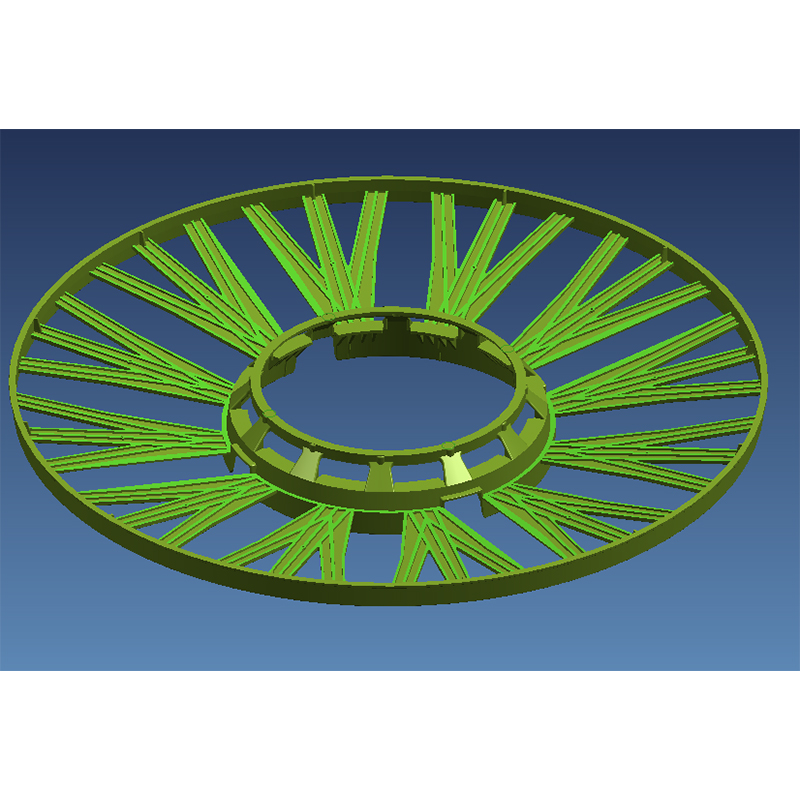

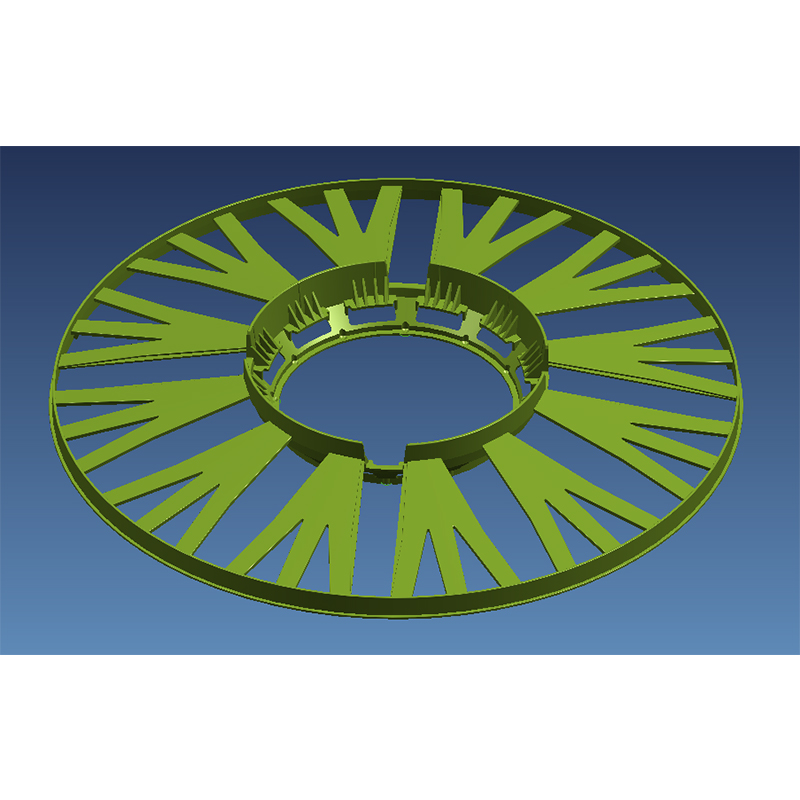

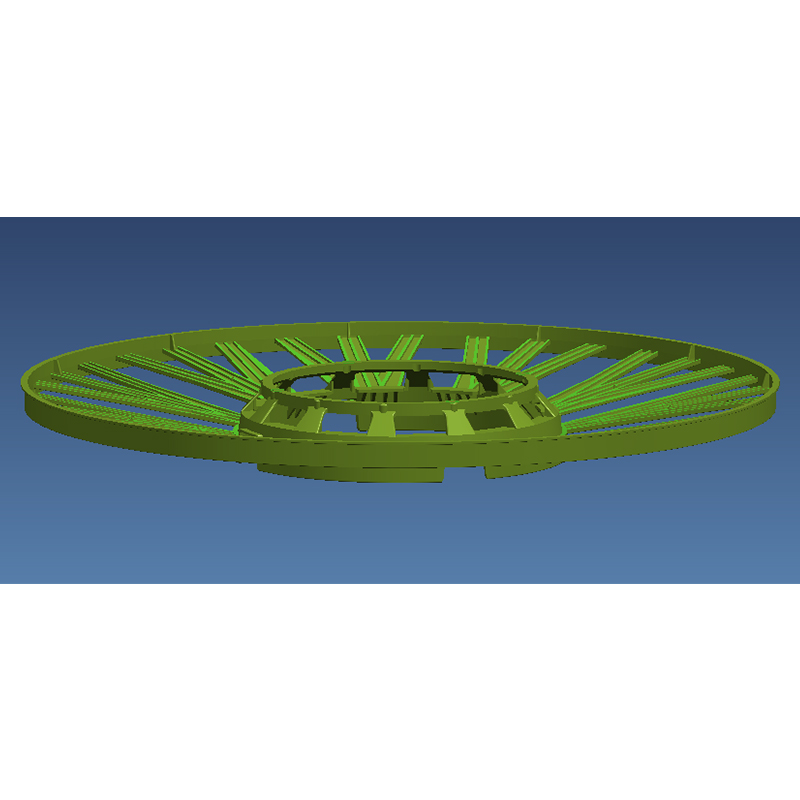

Core production business: Focus on tire matching and general hardware

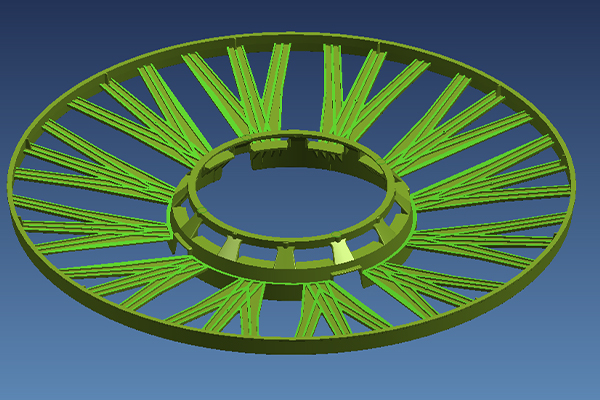

In the field of mechanical hardware and tire peripheral matching, the company focuses on the research and production of core products such as triangular rubber shaping discs, tire separators, bead separators, tire trays, etc., based on a deep understanding of industry demand. These products, as key supporting components in the tire production and processing process, directly affect the molding quality and production efficiency of tires. By optimizing the product structure design and selecting high-strength wear-resistant raw materials, the company not only has excellent load bearing performance and anti-aging ability, but also can adapt to the production needs of different specifications of tires. At present, the company has become a stable supplier of many well-known tire manufacturers.

Wholesale import and export business: deeply cultivating the fields of medical and high-end manufacturing

In the wholesale and import/export business sector, the company has precisely laid out high value-added areas, forming three core product lines: medical, automotive, and electronic appliances. Among them, the medical plastic product series covers various products such as medical plastic parts, medical plastic accessories, medical plastic tubes, medical plastic boxes, etc. It strictly follows the production standards of medical devices and is exported to multiple medical equipment production bases at home and abroad with excellent biocompatibility, sealing and sterility; Automotive plastic products focus on automotive interior parts, functional structural components, etc., adapting to the assembly needs of mainstream vehicle models; The new electronic and electrical plastic components are designed for consumer electronics, industrial appliances, and other fields, providing customized products with insulation, high temperature resistance, and precise dimensions. The diversified business layout enables the company to effectively resist the risk of single market fluctuations and achieve steady development.

Hardcore equipment strength, building a solid foundation of quality

To ensure product quality and production efficiency, the company spares no effort in investing in production equipment and has built a fully intelligent production system from raw material processing, precision molding to inspection and packaging. At the same time, it is equipped with a dedicated clean room workshop to meet the production requirements of high-precision and high cleanliness products. The core production and testing equipment configuration is as follows:

Precision injection molding equipment cluster

The company has a complete injection molding equipment system that can adapt to the production of plastic products of different specifications and accuracies. This includes 2 1600T injection molding machines, mainly used for the molding and processing of large plastic components; Two 800T injection molding machines and two 400T injection molding machines, suitable for the production of medium-sized precision products; Two 200T injection molding machines, four 90T injection molding machines, and four 60T injection molding machines meet the mass production needs of small high-precision products. Equipped with 6 sets of 30T vertical injection molding machines at the same time, it provides precise support for special process requirements such as insert injection molding, forming an injection molding production capacity that covers large, medium, and small specifications, taking into account both general and special processes.

Mold manufacturing and precision machining equipment

As the core link of injection molding production, the company attaches great importance to the construction of mold manufacturing capabilities and is equipped with a series of high-end processing equipment. This includes 2 850 type CNC machining centers, 1 1100 type CNC machining center, and 2 850 type CNC machining centers, which achieve high-precision milling of mold cavities; Two slow wire cutting devices ensure precise cutting of mold parts, with an accuracy of up to 0.001mm; four mirror spark machines are used for fine machining of mold cavities, making the surface roughness of the mold reach mirror level; Two CNC lathes provide assurance for the turning of mold components. In addition, four high-speed precision carving machines have further improved the efficiency and accuracy of mold processing, ensuring that the mold can quickly respond to product research and production needs.

Automation and testing equipment

In order to improve the level of production automation and product quality control capabilities, the company has equipped one automatic winding machine and one automatic packaging machine to achieve automated operation in the product packaging process. This not only improves packaging efficiency but also ensures packaging consistency. In terms of quality inspection, the company has introduced high-precision testing equipment such as three-dimensional coordinate instruments, which can comprehensively detect the dimensional accuracy and form and position tolerances of products, with a detection accuracy of 0.002mm, and prevent unqualified products from entering the market from the source.

Customer centric, building a full chain service system

Guided by customer needs and aiming for mutual benefit and win-win outcomes, "has been the business philosophy upheld by Yongshengsheng Hardware for over 20 years. In order to better serve customers, the company has established a full process service system from demand matching, scheme design, sample production, mass production to after-sales service. In the early stage of docking, professional business and technical teams will deeply understand the actual needs of customers and provide personalized product solutions based on industry experience; During the research and development production phase, strict process control is implemented to ensure timely delivery and stable quality of products; In the after-sales service stage, a dedicated service hotline and feedback channel are established to promptly respond to customers' technical inquiries, product maintenance and other needs, forming a service loop of "accurate pre-sales docking, efficient execution during sales, and thoughtful after-sales guarantee".

After more than 20 years of hard work, Yongshengsheng Hardware has always adhered to the development philosophy of "quality first, innovation as the soul", and continuously made breakthroughs in the fields of injection molding plastics and hardware manufacturing. In the future, the company will continue to increase investment in technology research and development, optimize product structure, expand broader market space, and strive to work together with domestic and foreign customers to achieve higher levels of mutual benefit and win-win results, writing a new chapter in the development of the enterprise!