The role of medical plastic products in healthcare

Definition and Importance of Medical Plastic Products

Medical plastic products refer to polymer materials specifically used in the medical field, which play an indispensable role in modern healthcare systems due to their unique physical and chemical properties and biocompatibility. With the advancement of materials science, medical plastics have evolved from simple packaging materials to an important component of high-tech medical equipment, greatly promoting the development of medical technology.

Main types and characteristics of medical plastics

Common types of medical plastics

Polyethylene (PE): used for infusion bottles and drug packaging

Polypropylene (PP): syringes, infusion equipment

Polyvinyl chloride (PVC): transfusion bags, infusion tubes

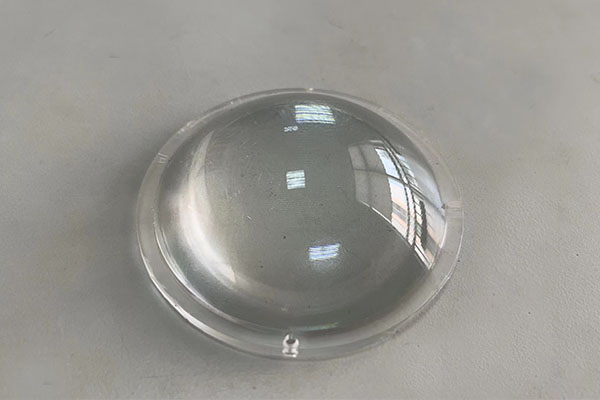

Polycarbonate (PC): blood dialyzers, surgical instruments

Polytetrafluoroethylene (PTFE): Artificial blood vessels, cardiac patches

Key performance requirements

Medical plastics must possess the following characteristics:

Excellent biocompatibility

good mechanical properties

chemical stability

Sterilizability

workability

The main applications of medical plastics in healthcare

Disposable medical supplies

Disposable plastic products such as syringes, infusion sets, blood collection needles, etc. greatly reduce the risk of cross infection. According to statistics, the use of disposable plastic medical devices has reduced hospital infection rates by over 70%.

Drug packaging system

Plastic is widely used in pharmaceutical packaging:

Eye medicine water bottle (LDPE)

Pill blister packaging (PVC/PVDC)

Infusion container (multi-layer co extruded film)

Implantable medical devices

Modern medical plastics have been applied to:

Artificial joint (ultra-high molecular weight polyethylene)

Cardiac stent (biodegradable polylactic acid)

Plastic material (silicone rubber)

Diagnostic and therapeutic equipment

The application of plastics in medical equipment includes:

In vitro diagnostic equipment casing

Ventilator tubing system

hemodialyzer

The technological development trend of medical plastics

Intelligent response materials

New medical plastics can respond to environmental stimuli such as temperature and pH, achieving functions such as controlled drug release and wound monitoring.

degradable material

Degradable materials such as polylactic acid (PLA) and polycaprolactone (PCL) are increasingly being used in temporary implants such as sutures and bone nails.

Antibacterial plastic

By adding antibacterial agents such as silver ions and quaternary ammonium salts, medical plastic products with long-lasting antibacterial properties have been developed.

The advantages and challenges of medical plastics

Main advantages

Lightweight and easy to use

High cost-effectiveness

High design flexibility

Good biosafety

Facing challenges

Environmental issues (disposal of medical plastic waste)

Some special properties (such as high temperature resistance) still have limitations

Durability study of long-term implants

Future prospects

With the advancement of materials science and manufacturing technology, medical plastics will continue to develop towards functionalization, intelligence, and environmental protection. The application of emerging technologies such as nanotechnology and 3D printing will further enhance the performance and applicability of medical plastics, bringing more innovative solutions to the healthcare industry.