Green transformation! Mass production of biodegradable medical plastic products to promote sustainable development in the healthcare industry

Under the dual promotion of the "dual carbon" goal and environmental policies, the demand for "plastic reduction" in the medical industry is becoming increasingly urgent. Recently, a certain environmental protection material company announced that the first fully degradable medical plastic accessories customization production line in China has been officially put into operation. The product is made of plant-based starch and polylactic acid (PLA) as raw materials, which can achieve complete degradation in the medical waste treatment environment, effectively solving the "white pollution" problem caused by traditional medical plastics and providing innovative solutions for the green transformation of the medical industry.

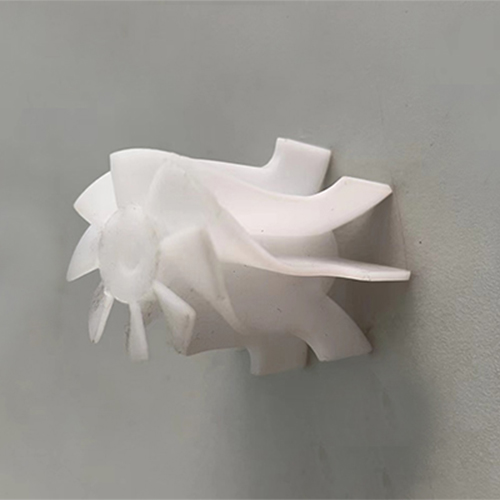

Traditional medical plastic products, such as disposable gloves, mask ear hooks, and bed sheets, often use non degradable polyethylene and polypropylene materials. After use, they need to be incinerated or buried, which can produce harmful gases. Landfilling takes hundreds of years to degrade, causing a serious burden on the environment. A biodegradable medical plastic developed by an environmentally friendly materials company uses special material modification technology to achieve complete degradation of the product into carbon dioxide and water within 180 days in a medical waste composting environment, while maintaining medical grade strength and flexibility. There is no harmful substance release during the degradation process. After testing, the mechanical properties such as tensile strength and elongation at break of the product have reached the plastic ware for hospital standard, and it has good barrier and puncture resistance, which can meet the needs of disposable medical supplies.

At present, the biodegradable product has been applied to more than 10 types of medical consumables such as disposable inspection gloves, mask ear hooks, and infusion patch substrates. In a trial in a certain secondary hospital, the proportion of non biodegradable plastics in medical waste has decreased by 55%, and the cost of waste disposal has been reduced by 30%. "The general manager of an environmental protection material company stated that in order to further promote product popularization, the company has also cooperated with medical waste treatment enterprises to establish a" production use degradation "full chain environmental protection system to ensure product degradation effect. Industry analysts point out that the mass production of biodegradable medical plastic accessories not only responds to national environmental policies, but also reduces environmental costs for medical institutions. In the future, with the maturity of technology and the decrease in costs, it is expected to gradually replace traditional medical plastic products and become the mainstream choice in the medical consumables market.