Accurate adaptation! Surgical specific medical plastic accessories components are launched, helping to further improve surgical accuracy

With the rapid development of minimally invasive surgical technology, there is an increasing demand for precision and miniaturization of surgical instruments. Recently, a precision manufacturing company has launched a dedicated Medical Plastic Accessories component for minimally invasive surgical instruments such as laparoscopy and arthroscopy. This product, with its ultra-high dimensional accuracy and mechanical stability, effectively improves the accuracy of surgical operations, reduces surgical trauma, and provides critical support for minimally invasive surgery.

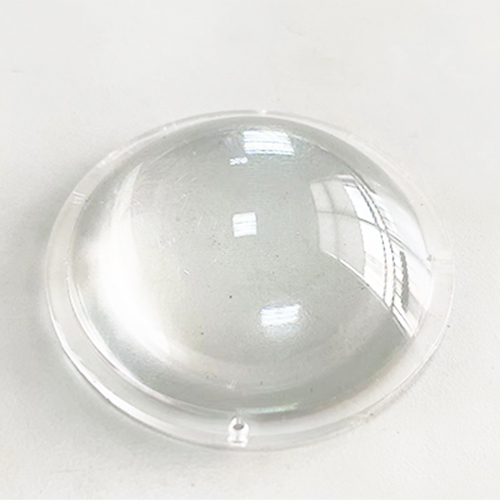

The core components of minimally invasive surgical instruments, such as catheter fittings, valves, endoscope housings, etc., need to achieve complex functions in extremely small spaces and withstand repeated operations and disinfection during the surgical process. The R&D team of a precision manufacturing company uses medical grade polyetheretherketone (PEEK) material, combined with five axis linkage precision injection molding technology, to control the dimensional tolerance of the components within ± 0.005mm and the surface roughness Ra ≤ 0.02 μ m, ensuring perfect compatibility between the components and other parts of the instrument, and avoiding liquid leakage or operational lag caused by excessive clearance. At the same time, the material has excellent sterilization resistance and can withstand various sterilization methods such as high temperature steam sterilization at 134 ℃ and gamma ray sterilization. The repeated sterilization can reach more than 100 times, greatly reducing the equipment procurement cost of medical institutions.

In a knee arthroscopy surgery at a certain orthopedic hospital, the use of this specialized plastic component instrument improved the stability of the doctor's hand feel by 40%, shortened the average surgical time by 20 minutes, and significantly shortened the patient's postoperative recovery period. The technical director of a precision manufacturing company stated that the product currently covers more than 10 types of minimally invasive surgical instruments such as laparoscopy, thoracoscopy, and arthroscopy, and has established long-term cooperation with many well-known medical device manufacturers in China. In the future, the company will also develop higher precision medical plastic product components for robot assisted surgical instruments, promoting the development of minimally invasive surgical technology towards greater precision and safety.