What is the process and purpose of tire partition?

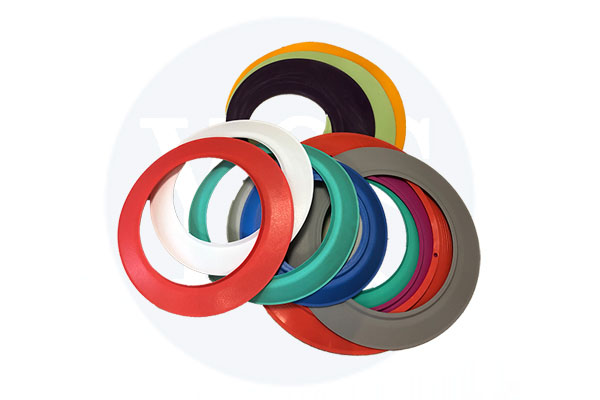

Basic concept of tire partition

Tire partition is an important component in the tire manufacturing process, mainly used to separate different layers of materials inside the tire, ensuring tire structural stability and performance optimization. Against the backdrop of rapid development in China's tire industry, significant progress has been made in tire partition technology.

The main production process of tire separators in China

1. Raw material selection and processing

Chinese tire manufacturing enterprises generally use domestically produced high-quality rubber as the basic material, combined with imported additives, to ensure the performance of the partition through precise proportioning. In recent years, nano composite materials developed in China have shown excellent performance in the application of separators.

2. Rolling forming process

Chinese tire factories generally adopt automated rolling production lines, which control the thickness of the partition between 0.3-1.2mm through precision rolling with multiple rollers, and the tolerance can be controlled within ± 0.03mm.

3. Sulfurization process

Adopting China's independently developed intelligent vulcanization control system, the temperature is precisely controlled between 150-160 ℃, and the time varies from 5-15 minutes depending on the specifications, ensuring that the physical properties of the partition meet the standards.

4. Surface treatment technology

Some leading enterprises in China have applied plasma surface treatment technology, which has increased the surface energy of separators by more than 30% and significantly improved the adhesion performance with other tire components.

The main purpose of tire partition

1. Structural separation function

In various types of tires manufactured in China, separators are mainly used to separate the carcass ply layer from the belt layer, preventing different materials from interpenetrating and affecting performance.

2. Stress distribution optimization

The partition structure designed by Chinese engineers through computer simulation can effectively disperse the stress during tire driving and extend the service life of tires by 15-20%.

3. Shock absorption and noise reduction function

The honeycomb structure partition using Chinese patented technology can reduce tire noise by 3-5 decibels and improve driving comfort.

4. Thermal management function

The heat-conducting partition developed in China can optimize the internal heat distribution of tires, reduce the temperature in high-temperature areas by 8-10 ℃, and improve the safety of high-speed driving.

Technological Innovation of Chinese Tire Diaphragm

In recent years, Chinese tire companies have made multiple breakthroughs in partition technology:

Graphene reinforced partition: strength increased by 40%, thermal conductivity increased by 50%

Degradable and environmentally friendly partitions: meeting China's increasingly stringent environmental requirements

Intelligent sensing partition: integrated micro sensors, real-time monitoring of tire status

Market Application Status

As the world's largest tire producer, China produces over 500000 tons of tire partition related materials annually. The partition technology of leading domestic enterprises such as Zhongce Rubber and Linglong Tire has reached the international advanced level. The products are not only supplied to the domestic market, but also exported to high-end markets such as Europe and America.

With the continuous development of China's automobile industry and the continuous innovation of tire technology, the tire partition process will continue to develop towards high performance, lightweight, and intelligence, contributing to the transformation of Chinese manufacturing to Chinese creation.