The key application of bead separators in tire manufacturing

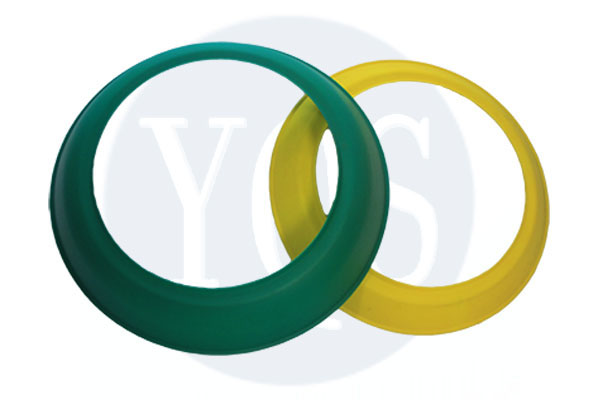

Basic concepts and structures of tire bead separators

The bead separator is an important functional component in the tire manufacturing process, located at the bead area of the tire. Its main function is to isolate and support the bead wire harness. This special component is usually made of high-strength rubber composite material and has the following typical structural characteristics:

Thickness: usually between 1.5-3.0mm

Hardness: Shore hardness 70-85 degrees

Shape: Designed into a specific contour based on tire specifications

Material: Generally, a composite formula of natural rubber and synthetic rubber is used

The core function of the tire bead partition

1. Structural isolation function

The bead partition effectively separates the bead wire bundle from the carcass ply, preventing mutual interference and friction damage between different material components. This isolation function can:

Maintain the structural integrity of the tire bead area

Reduce stress concentration between materials

Extend the service life of tires

2. Stress distribution optimization

Through precise design of tire bead separators, it is possible to:

Uniformly distributed stress in the tire bead area

Buffer the impact load during driving

Reduce the risk of fatigue damage in the bead area

3. Manufacturing process assistance

During the tire forming process, the bead separator plays a crucial role in assisting the manufacturing process

Fix the position of the tire bead wire

Maintain dimensional stability during molding

Increase productivity

Material selection of tire bead separator

Main material composition

Rubber matrix: usually using a composite system of NR/SBR/BR

Reinforcing filler: carbon black or white carbon black

Adhesive system: resorcinol formaldehyde white carbon black system

Antioxidant: Combination of antioxidant and ozone inhibitor

Material performance requirements

High modulus (ensuring support)

Low heat generation (reducing heat accumulation)

Excellent adhesion performance

Good fatigue resistance

Production process of tire bead separator

1. Mixing process

Using an internal mixer for multi-stage mixing, strictly controlling:

Mixing temperature (usually not exceeding 155 ℃)

Mixing time (total time approximately 8-12 minutes)

Feeding sequence (add raw rubber and some fillers first)

2. Rolling forming

Preparation of partition film through precision rolling equipment, key control points:

Thickness tolerance (± 0.05mm)

Width consistency

SURFACE QUALITY

3. Cutting and pre forming

According to the tire specifications:

Angle cutting (usually 30-45 °)

length control

End overlap treatment

Key points for quality control of tire bead separators

1. Dimensional accuracy control

thickness deviation

Width consistency

length tolerance

2. Physical performance testing

Hardness test

tensile strength

tear strength

adhesive property

3. Durability assessment

Dynamic fatigue testing

heat aging property

Ozone aging test

Evaluation of the application effect of tire bead separators

Performance improvement performance

30-50% improvement in tire bead durability

Improvement of tire uniformity by over 20%

Reduce early damage to the tire bead area

Economic Benefit Analysis

Reduce tire repair rate

Extend the service life of tires

Improve product market competitiveness

Future Development Trends

Application of New Materials: Developing Higher Performance Nanocomposites

Structural optimization: Optimizing partition shape design through finite element analysis

Intelligent Manufacturing: Introducing Automated Inspection and Intelligent Control Systems

Environmental protection direction: Developing recyclable and environmentally friendly partition materials

As a key component of tires, the technological progress of tire bead separators will continue to promote the improvement of tire performance and the optimization of manufacturing processes.