Trinity: Collaborative Symphony of Apex Holder, Apex Disc, and PP Tire Bead Plastic Plate

In the grand symphony of tire manufacturing, tire bead partition, triangle rubber tire partition, and triangle rubber tire bead partition are like three harmonious musicians, each playing unique notes and composing a high-quality symphony together. Although they are in different processes, they are interrelated and jointly build the "foundation ring" of the tire - the structural integrity and reliability of the bead area.

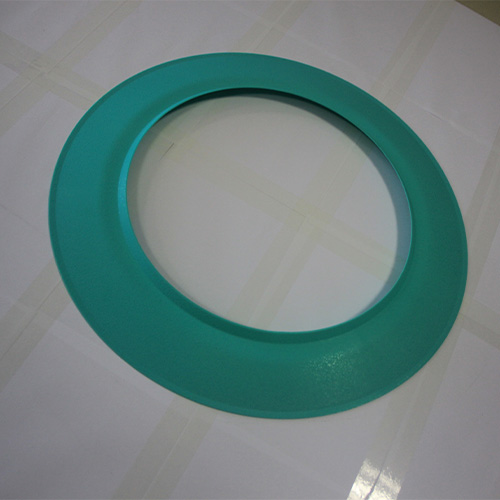

Triangle rubber shaping disc ensures precise formation of tire bead reinforcement structure; Special plastic products for tire factories ensure a clean and defect free vulcanization process; Special plastic accessories for tire factories provide physical protection and sealing support at the user end. The collaboration of the three forms a full chain protection system from "manufacturing" to "use".

A certain tire company proposed a "triple protection system for tire beads" and optimized the three systems: precise pressing of triangular rubber on the shaping disc, ensuring no adhesion during vulcanization on the partition, and preventing wear and tear on the PP board during use. After implementation, the durability of the product's tire beads increased by 50%, the customer complaint rate decreased by 60%, and the high-end market share significantly increased.

This is not only a combination of components, but also a victory of systems thinking. When every detail is carefully considered, industrial manufacturing becomes a precise art form. These three seemingly ordinary accessories, with the power of silence, support every safe journey and write an outstanding chapter in the modern tire industry.