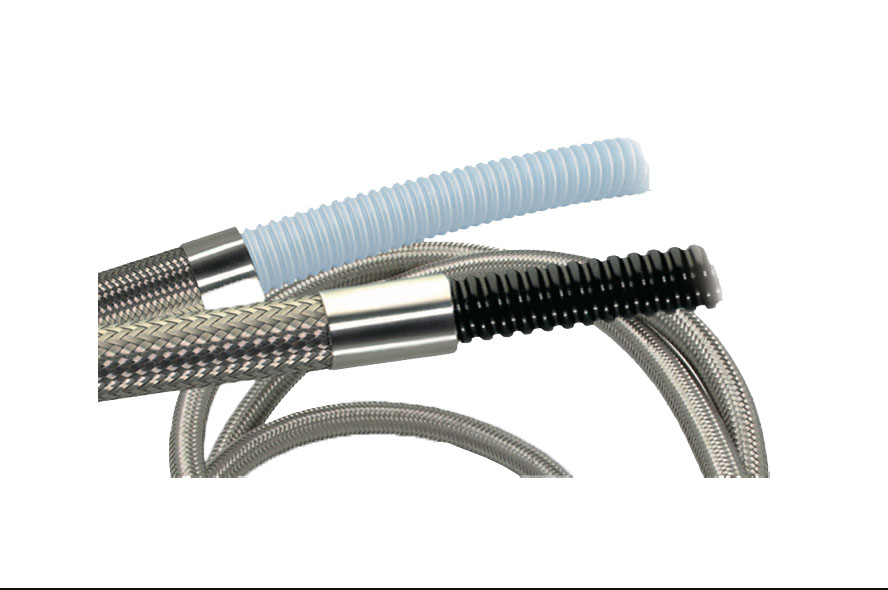

Ultra Soft Ptfe Fep

- Changshu Eternal Prosperity

- Changshu Eternal Prosperity

Product performance:

1. Working temperature range: -65 ℃~+260 ℃

2. Corrosion resistance, high temperature resistance, and melt resistance

3. Non viscous, non wet, non flammable

4. Low permeability, low friction coefficient

5. Anti weathering and anti-aging

6. Good electrical performance

Origin: China

Product performance:

1. Working temperature range: -65 ℃~+260 ℃

2. Corrosion resistance, high temperature resistance, and melt resistance

3. Non viscous, non wet, non flammable

4. Low permeability, low friction coefficient

5. Anti weathering and anti-aging

6. Good electrical performance

Product advantages:

1. Advantages: Long service life, no need for frequent replacement, stable temperature, reduced defects

After sales service:

If there is air leakage in the ultra soft and bendable PTFE corrugated pipe before 12 months of use, our company will replace the defective product free of charge.

Company Introduction:

The company is expanding production and relocating, and the factory area has been expanded to 3080 square meters. Continuously enriching the product line, focusing on areas such as automotive interior parts and medical devices, with an annual production capacity increased to 3 million sets. The design team uses design software such as Unigraphics, Mastercam, Powerwill, Catia, etc. to provide professional services in product design, part deepening, mold design, mold making, and injection molding. The production equipment includes 3 CNC machining centers, 3 Beijing precision carving centers, 4 wire cutting centers, and mold making equipment such as lathes, milling machines, grinders, and electric discharge machines. We also provide 16 injection molding processing equipment for 50-800 tons.

Company goal:

To improve product quality, actively develop new products, and enable Chinese products to enter the leading field of international similar products.

FAQ

Where is PTFE corrugated pipe used?

Teflon corrugated pipes (also known as polytetrafluoroethylene corrugated pipes) are widely used in various industries due to their excellent corrosion resistance, high temperature resistance, low friction coefficient, and good flexibility. The following is a detailed introduction to its main application scenarios:

1、 Chemical industry

Pipeline connection and compensation: In chemical production, PTFE corrugated pipes can be used as flexible connectors in pipeline systems that transport corrosive media (such as strong acids, strong bases, organic solvents, etc.) to compensate for displacement caused by temperature changes, vibrations, or installation deviations, while avoiding corrosion of the pipeline by the medium.

Pump and valve connection: There are often vibrations and displacements at the connection between pumps, valves, and pipelines in chemical equipment. Teflon corrugated pipes can play a buffering and sealing role to prevent the leakage of corrosive media.

2、 Electronic and electrical industry

Wire and cable protection: In high temperature and corrosive environments (such as welding areas of electronic components and electrical wiring in chemical workshops), PTFE corrugated pipes can be used as protective sleeves for wires and cables to isolate damage from the external environment.

Instrumentation pipeline: In precision electronic instruments and meters, small pipelines used to transport coolant and gas often use PTFE corrugated pipes, which have smooth inner walls, are not easy to scale, and can adapt to temperature changes causing expansion and contraction.

3、 Mechanical manufacturing industry

Hydraulic and pneumatic systems: In the transmission pipelines of hydraulic oil, compressed air and other media, PTFE corrugated pipes can be used as flexible joints to absorb system vibration and pipeline installation errors, while withstanding the erosion of hydraulic oil and other media.

Machine tool cooling pipeline: During the machining process of the machine tool, coolant (which may contain corrosive components such as cutting fluid) needs to be transported through pipelines. Teflon corrugated pipes can resist the corrosion of coolant and have good flexibility, making it easy to follow the movement of machine tool components.

4、 Food and pharmaceutical industry

Fluid conveying pipeline: Teflon material has the characteristics of non-toxic, washable, and non stick, which meets the hygiene standards of the food and pharmaceutical industries. Therefore, it is commonly used for conveying food raw materials, drugs, purified water, etc., such as infusion pipelines in pharmaceutical equipment and sauce conveying pipelines in food processing.

Disinfection equipment connection: In high-temperature steam disinfection equipment, PTFE corrugated pipes can withstand high-temperature steam corrosion and serve as pipeline connections to ensure the sealing of the disinfection process.

5、 Aerospace and Military Industry

Spacecraft piping system: Spacecraft will experience extreme temperature changes (-200 ℃ to 260 ℃) and radiation environments in space. Teflon corrugated pipes can maintain stable performance in such environments and are used to transport critical media such as fuel and coolant.

Military equipment pipelines: Hydraulic and fuel pipelines in military equipment (such as fighter jets and ships) need to withstand vibration, impact, and harsh environments. The weather resistance and reliability of PTFE corrugated pipes make them an ideal choice.

6、 Other fields

Environmental protection equipment: In the treatment of acidic and alkaline wastewater and exhaust gas in environmental protection equipment, PTFE corrugated pipes are used to transport corrosive waste liquids or gases to prevent equipment corrosion and leakage.

In the field of new energy, such as fuel cell systems, pipelines used to transport media such as hydrogen and coolant, and the chemical resistance and sealing properties of PTFE can ensure the safe operation of the system.

In summary, the core application of PTFE corrugated pipes is to utilize their characteristics of "corrosion resistance, temperature resistance, flexibility, and cleanliness" to solve the connection, sealing, and compensation problems of conventional metal or plastic pipelines in harsh environments. They are important components in the industrial field to cope with complex working conditions.