Plastic Tray: The Neglected 'Breath Guardian'

During the tire vulcanization process, the high temperature and high pressure environment is like a "purgatory test". And Plastic tray, this seemingly ordinary isolation material, is actually the "breathing guardian" that ensures tire quality.

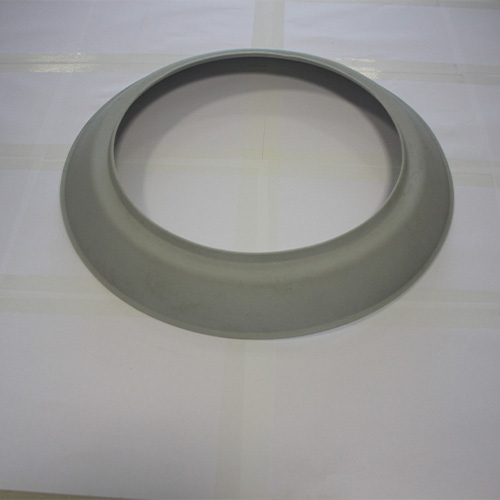

It is located between the tire blank and the mold, undertaking the triple mission of anti sticking, thermal conductivity, and exhaust. Traditional partitions are prone to aging and residue, which affects the surface smoothness of tires. The new high-temperature resistant fluororubber Circular plastic flap can withstand temperatures of over 300 ℃ and maintain stable performance even after hundreds of repeated uses.

What is even more commendable is that some high-end Bead caps already have a "microporous breathable" function - allowing water vapor to be released during the initial stage of vulcanization to prevent porosity; Automatic closure in the later stage to avoid overflow of adhesive material. Like a 'smart skin', it regulates the microenvironment inside the mold.

An engineer from a tire factory likened it to: "Without a good bead separator, it's like without qualified baking paper. Even the best dough cannot bake a perfect cake. ”This small partition is the mastermind behind the "perfect skin" of the tire.